Hybrid Parallelization for Solidification and Fluid Dynamics

Key Solutions

- Combine phase-field simulation with fluid dynamics.

- Enhance performance by parallelization.

- Selection of wetting parameters for each phase.

- Exchange of forces between fluid and solid.

Advanced Features

- Lattice-Boltzmann method as fluid dynamics solver.

- Two fluid phases separating liquid and vapor.

- Simulation of solid collisions.

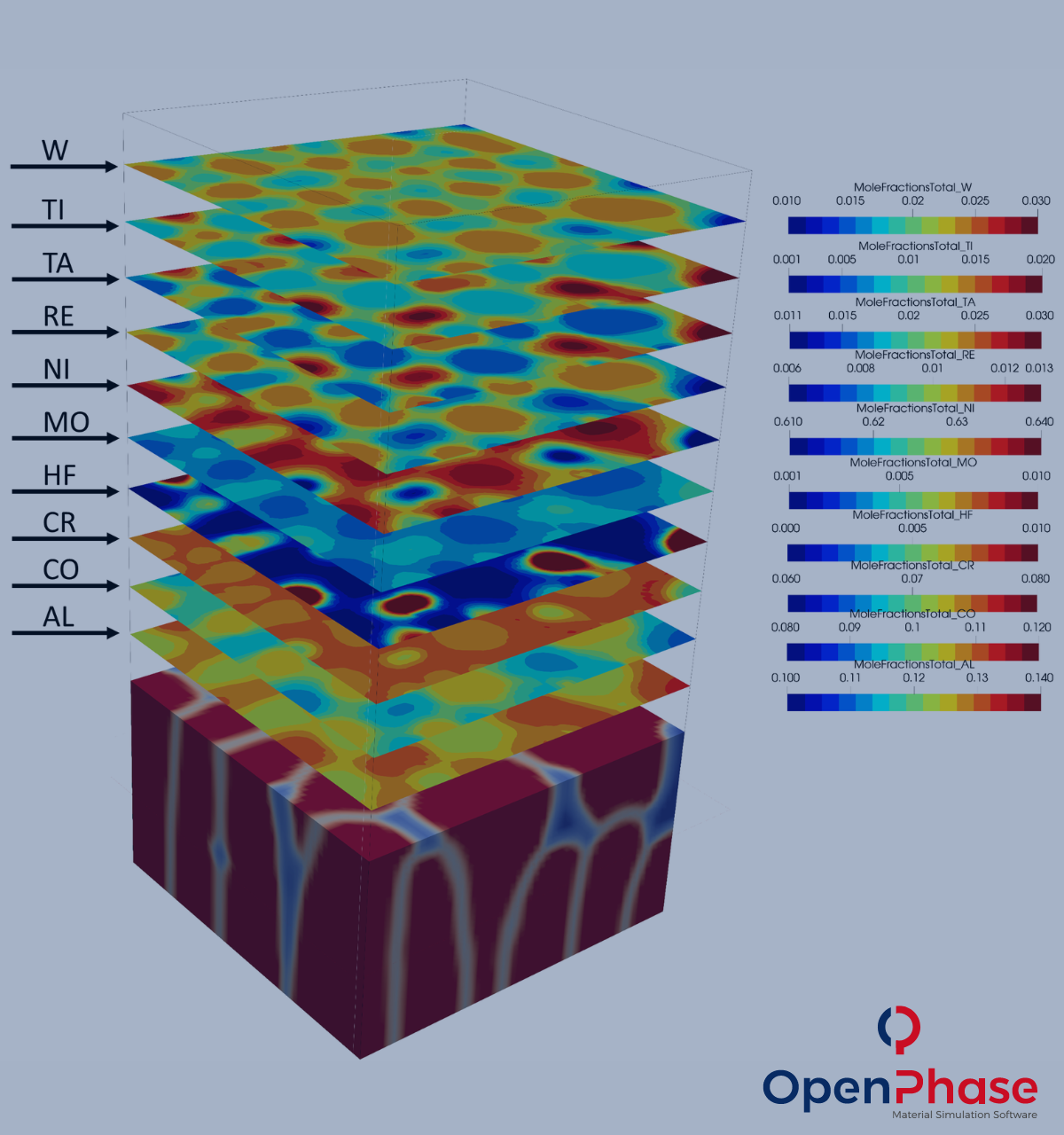

- Transport of element concentrations due to flow.

- Hybrid parallelization combining OpenMP and MPI.

Case Study: Mg-Al Alloys

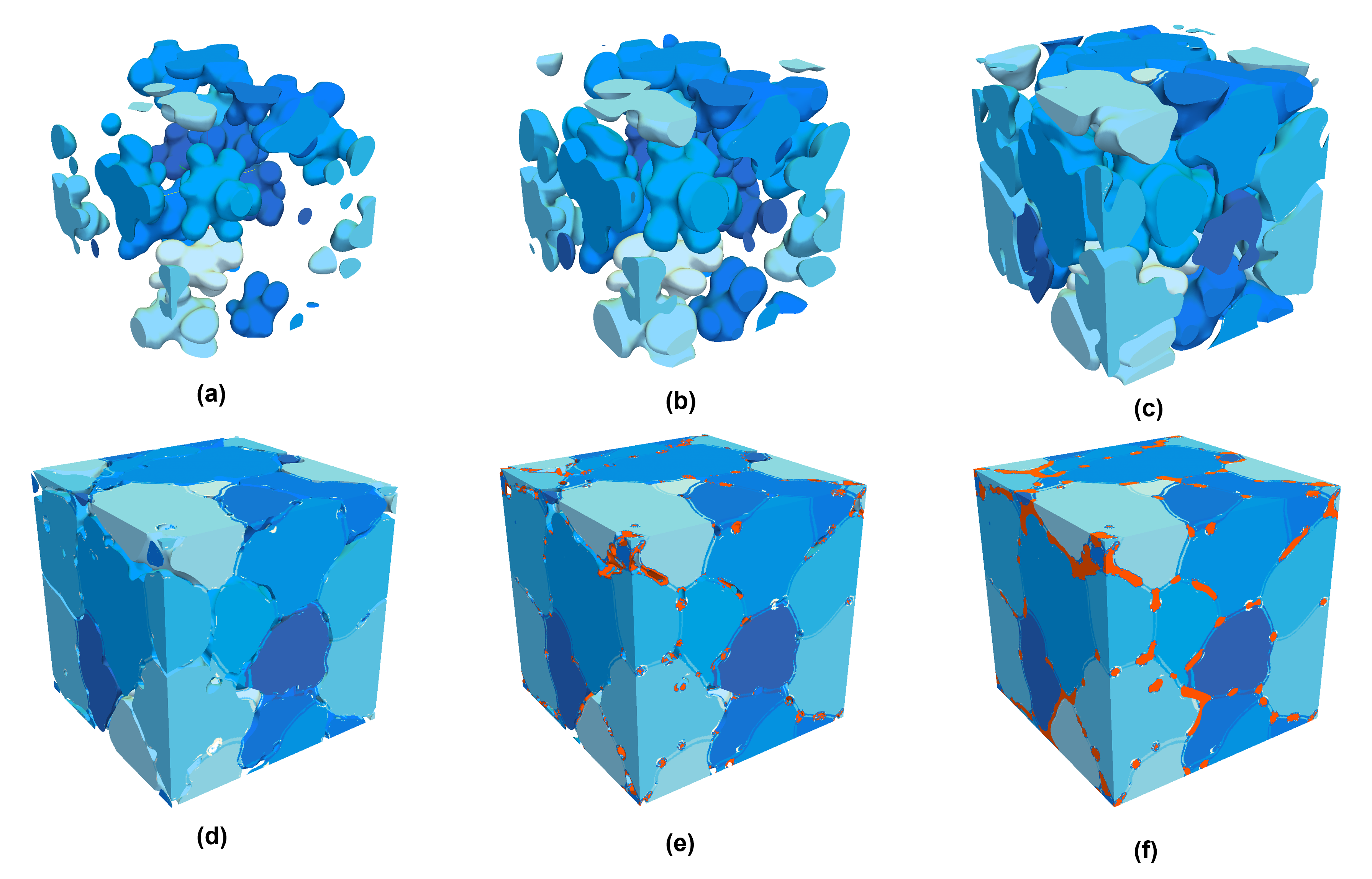

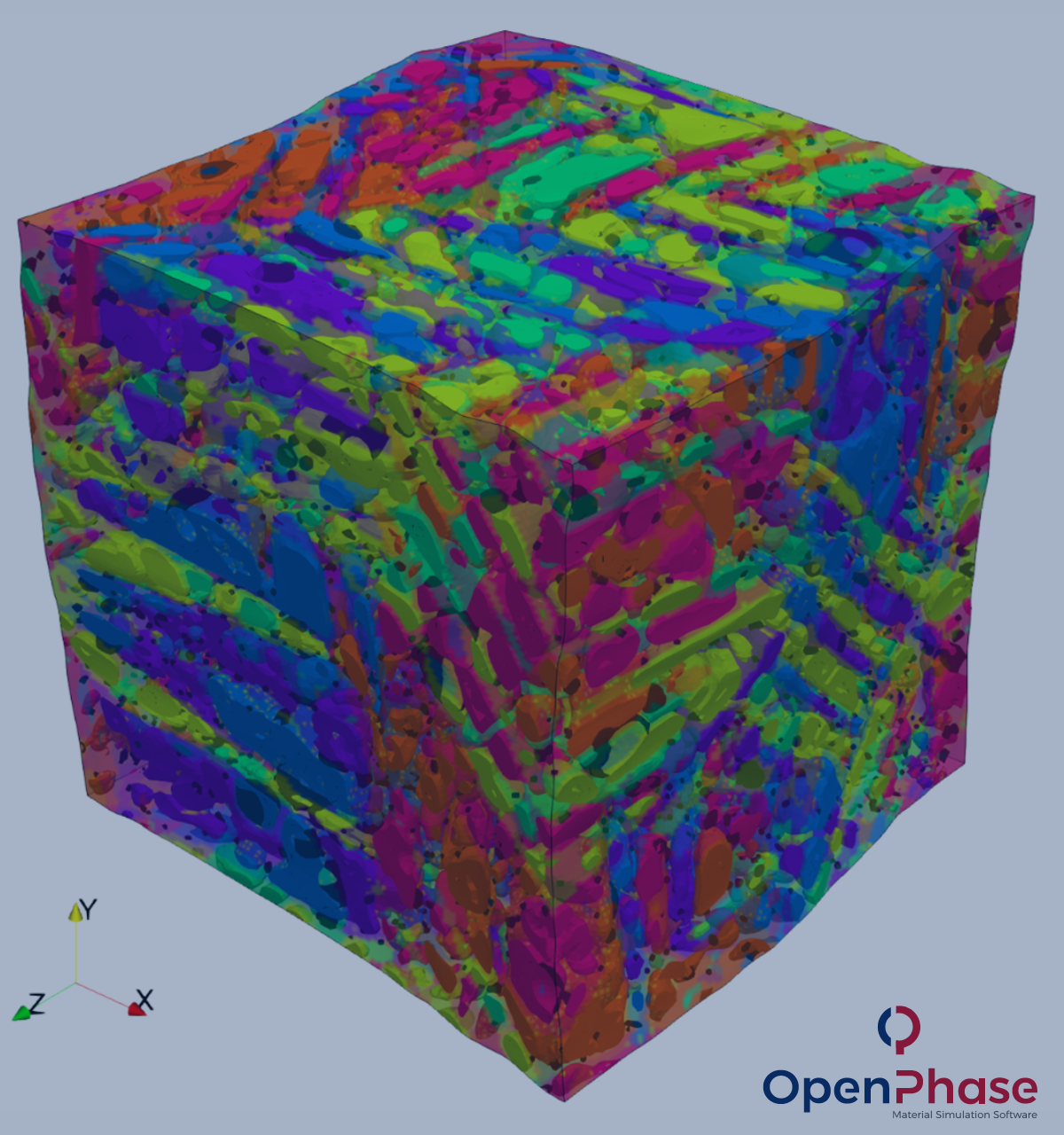

Due to their low density, Mg-Al alloys are interesting materials for lightweight structural applications in automotive and aerospace engineering and high-end consumer electronics. They usually consist of dendrites of the primary HCP-Mg-α phase and an interdendritic eutectic, which consists mainly of the inter-metallic Mg17Al12-β-phase as Mg-Al alloys are usually sensitive to corrosion. However, enclosing the α-phase dendrites with the β-phase improves the corrosion resistance. Therefore, optimizing process parameters is crucial to avoid direct contact between α-phase dendrites in the resulting microstructure.

OpenPhase Capabilities

Discover how OpenPhase's advanced phase-field modeling capabilities can revolutionize your fluid dynamics simulations

Phase-Field and Fluid Dynamics Integration

-

Lattice-Boltzmann Method Advanced fluid dynamics solver for accurate flow simulations.

-

Two-Phase Fluid Simulation Separate liquid and vapor phases using mean-field potential.

-

Wetting Parameters Customizable wetting parameters for each phase interaction.

-

Force Exchange Accurate modeling of force interactions between fluid and solid phases.

-

Solid Collision Simulation Advanced modeling of solid particle interactions and collisions.

-

Concentration Transport Accurate tracking of element concentrations in fluid flow.

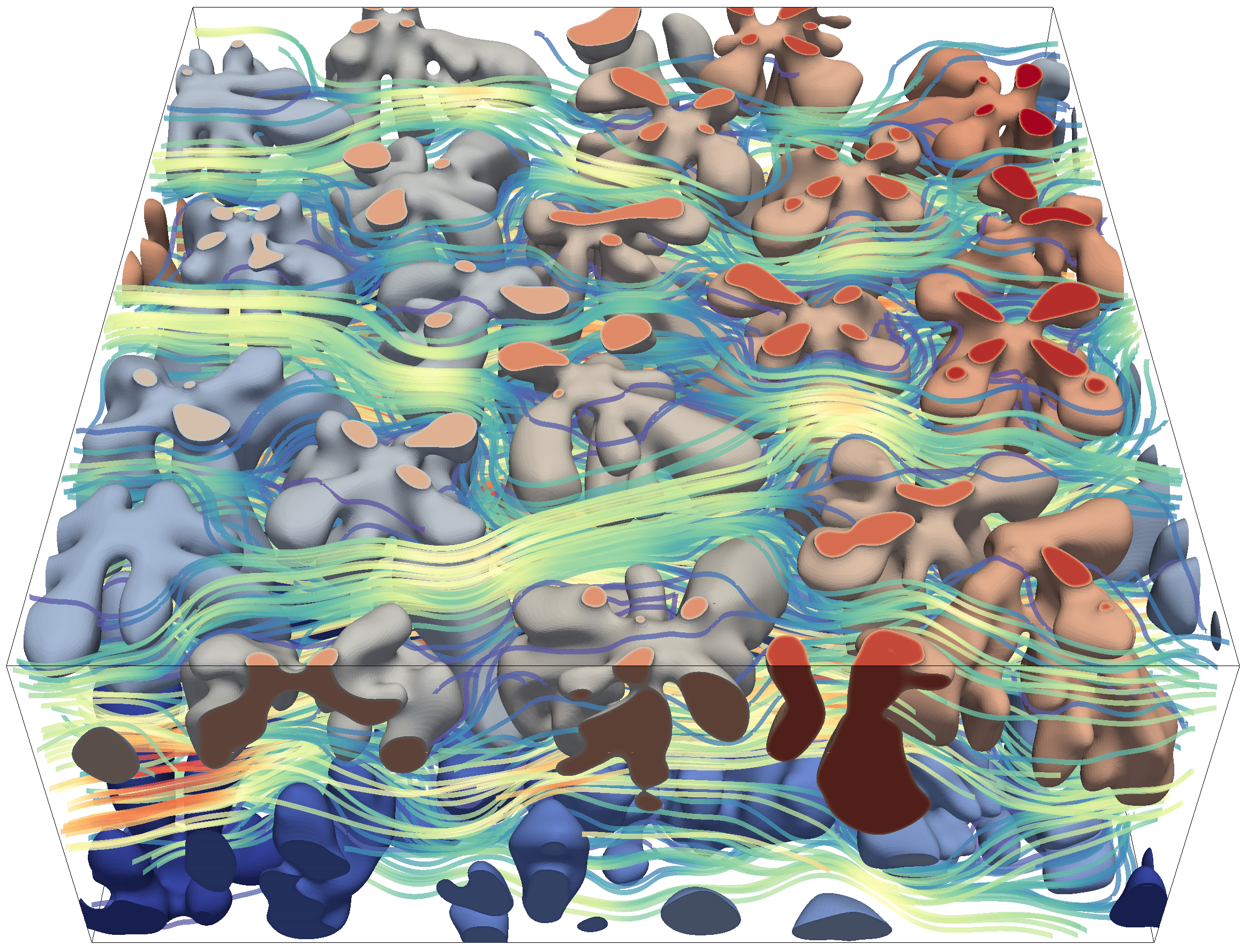

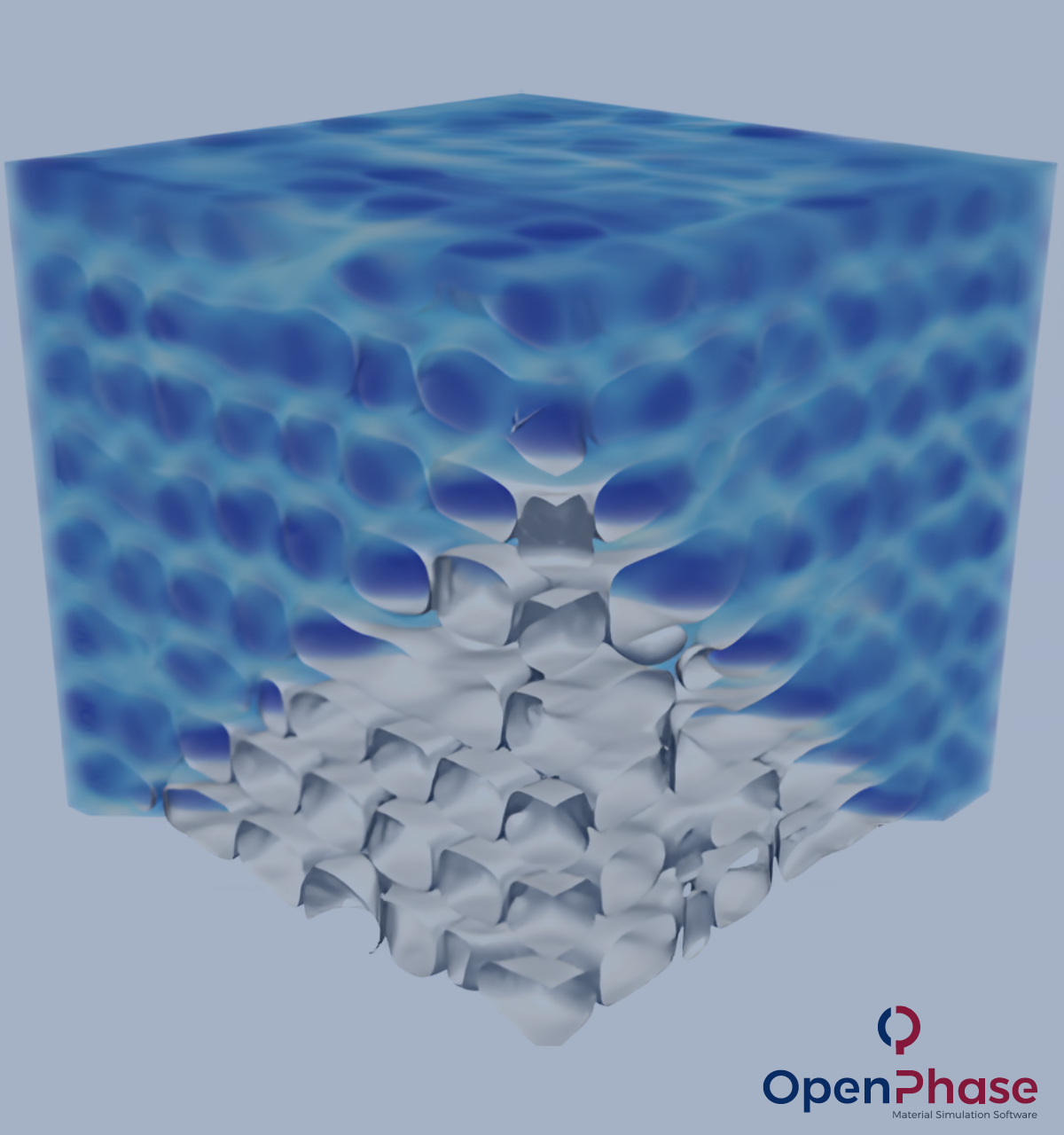

In this example (see fig 2), the solidification of the primary α-phase dendrites has been simulated using a hybrid parallelization with MPI and OpenMP. Figure 3 shows the streamlines for a flow through the microstructure shown in fig 2 during the growth phase.

MPI and OpenMP Integration

Create large-scale simulations using advanced parallelization techniques

Advanced Parallelization Features

-

Hybrid Parallelization Efficient combination of OpenMP and MPI for optimal performance.

-

FFTW Integration Compatible with MPI-version of the popular fast Fourier transformation software FFTW for mechanics solver.

-

Large-Scale Simulations Utilize computational resources from multiple compute nodes for extensive simulations.

OpenMP distributes the computational work into multiple threads in shared memory. MPI allows the distribution of work into processes between different computational resources, which do not necessarily share memory. It requires communication of data between processes. Any version of OpenPhase supports OpenMP.

Ready to unlock the full power of parallel computing? Get your network license for OpenPhase MPI today - each computational node needs just one network seat! Contact us

Related Topics

High Temperature Superalloys

Discover advanced simulation solutions for high temperature superalloy applications.

Tempered Martensite

Explore the transformation and properties of tempered martensite in steel materials.

Additive Manufacturing

Learn about advanced simulation solutions for additive manufacturing processes.