OpenPhase example

Tempered Martensite

Key Solutions

- Determine martensite start and finish dependent on the quenching rate.

- Tailor amount and distribution of carbides.

- Optimize the heat treatment for each specific steel grade.

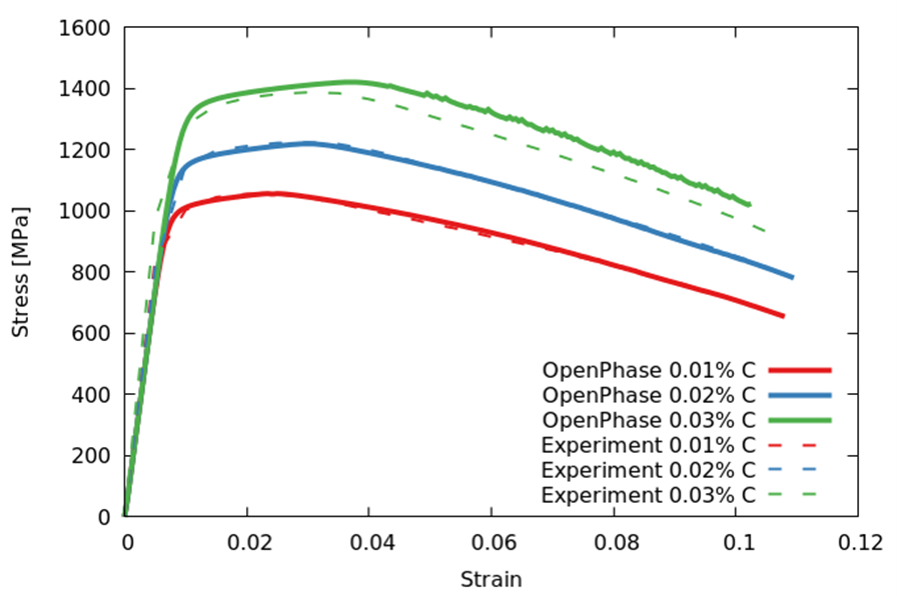

- Determine flow curves of tempered martensite.

Advanced Features

- Martensite start prediction based on driving forces

- Multiple modules for carbide nucleation

- Growth stage based on local carbon supersaturation

- Ripening stage determined by multi-component diffusion

Understanding Tempered Martensite

Mechanical properties of steel vary significantly based on the heat treatment process. Tempered martensite is an exceptional example where properties can be precisely tuned to achieve:

- High hardness and strength

- Superior wear resistance

- Enhanced corrosion resistance

- Excellent ductility and toughness

OpenPhase Solutions

OpenPhase Capabilities

Discover how OpenPhase's advanced phase-field modeling capabilities can revolutionize your martensite simulations

- Martensite start is predicted based on driving forces to transformation using alloy thermodynamics

- Martensite finish is determined by transformation kinetics

- Internal heat release due to transformation is considered

- Results are transformed to virtual dilatometer curves

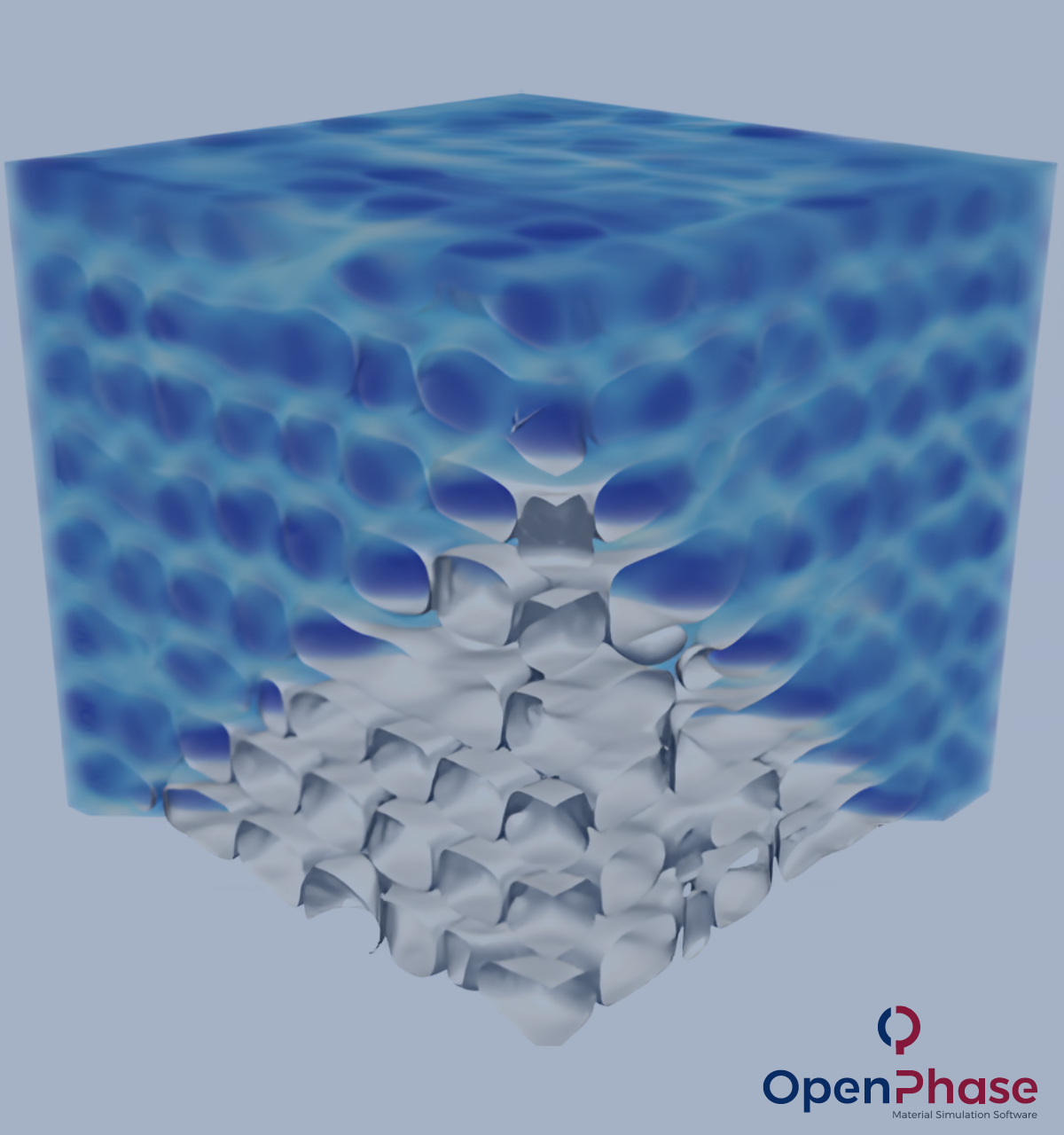

- Multiple modules for carbide nucleation (random statistics, dedicated sites, interfaces, junctions, local residual strain)

- Growth stage based on local carbon supersaturation and tetragonal distortion relaxation

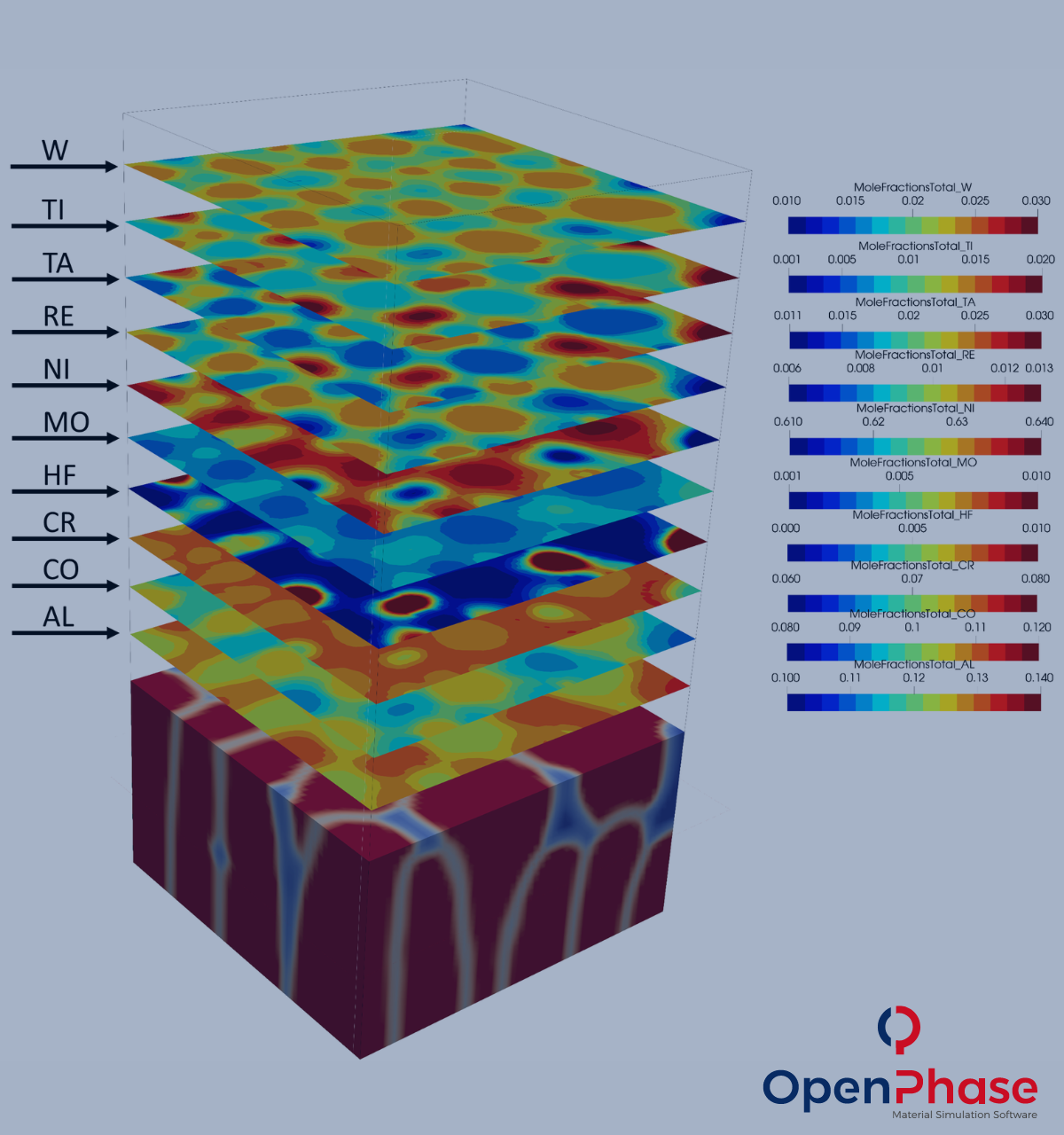

- Ripening stage determined by multi-component diffusion and solute element cross-interaction

- Consideration of lattice strain effects on diffusion, coherency strain, and coherency loss during growth

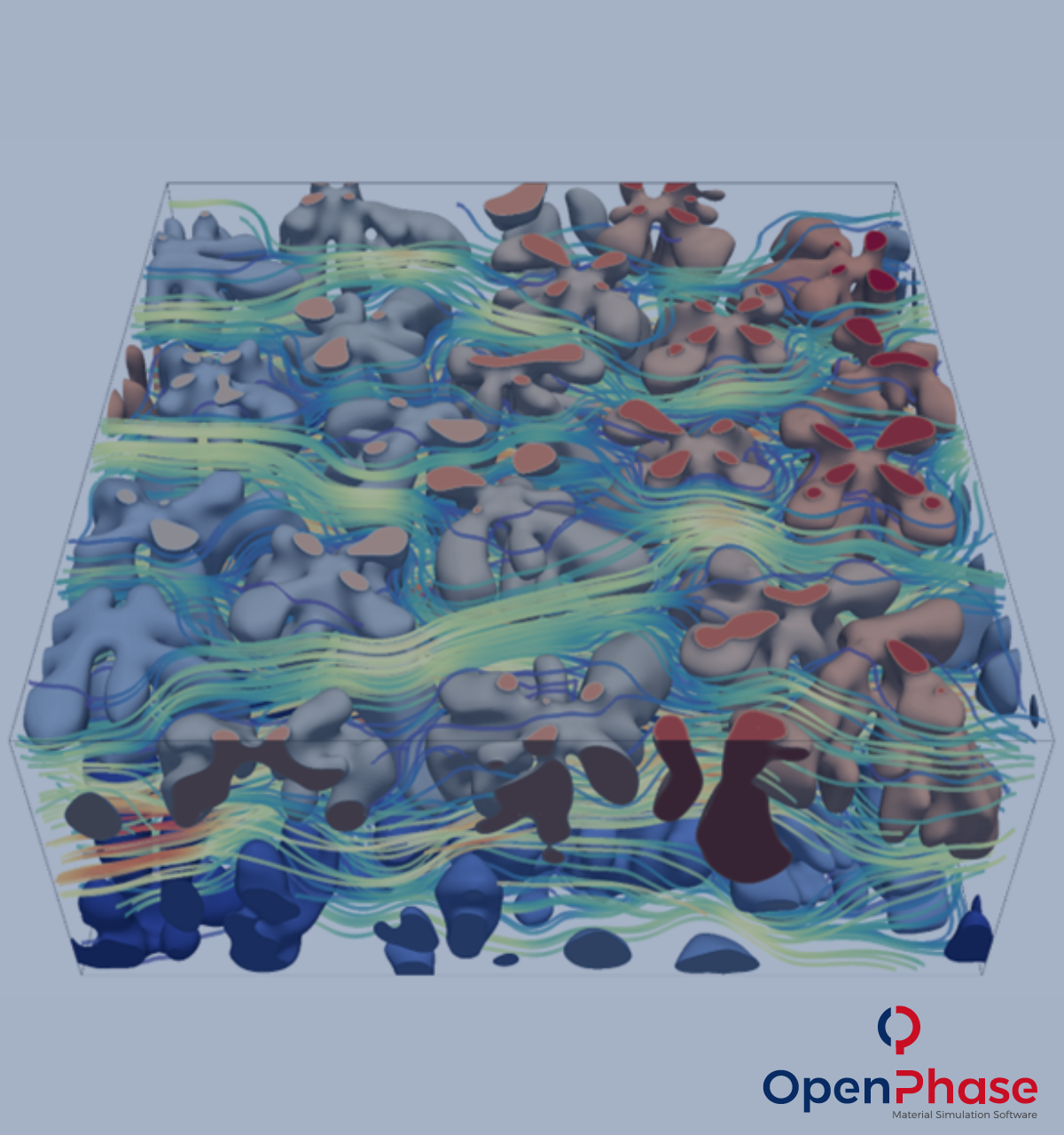

- Investigate system response to different heat extraction conditions

- Tailor heat extraction through inverse optimization

- Test nucleation conditions of various carbide populations and competitive growth

- Investigate microalloying effects on precipitation and mechanical stability

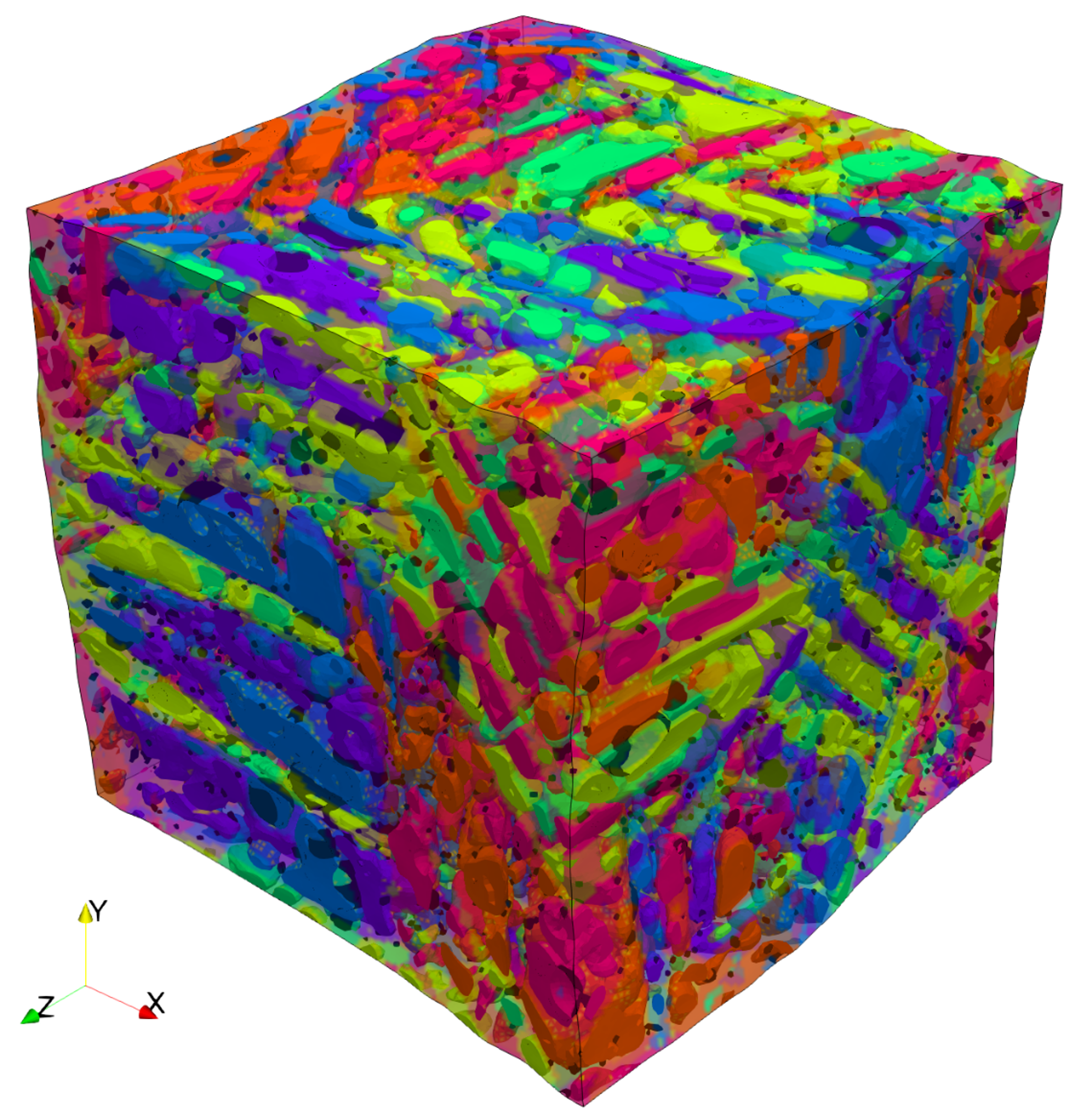

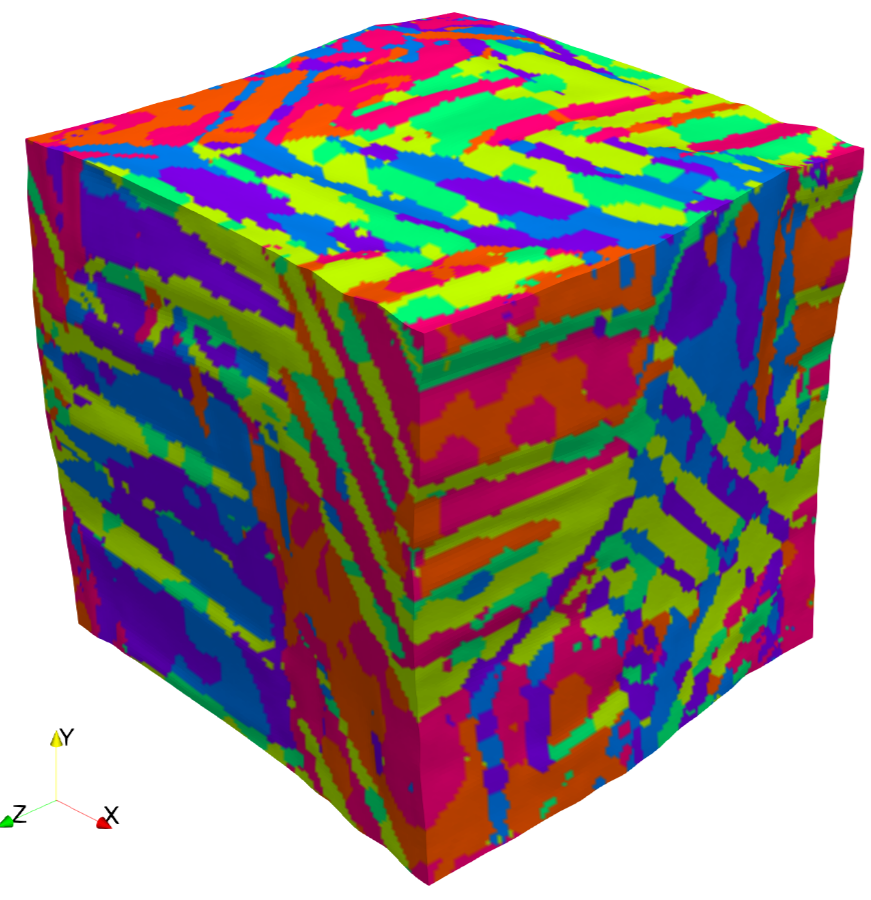

- Optimize crystal plasticity models with sparse experimental input

- Interpolate and extrapolate flow rules for FE analysis at sample scale

- Determine rules as a function of local alloy composition

- Tailor heat treatment process for optimized mechanical response

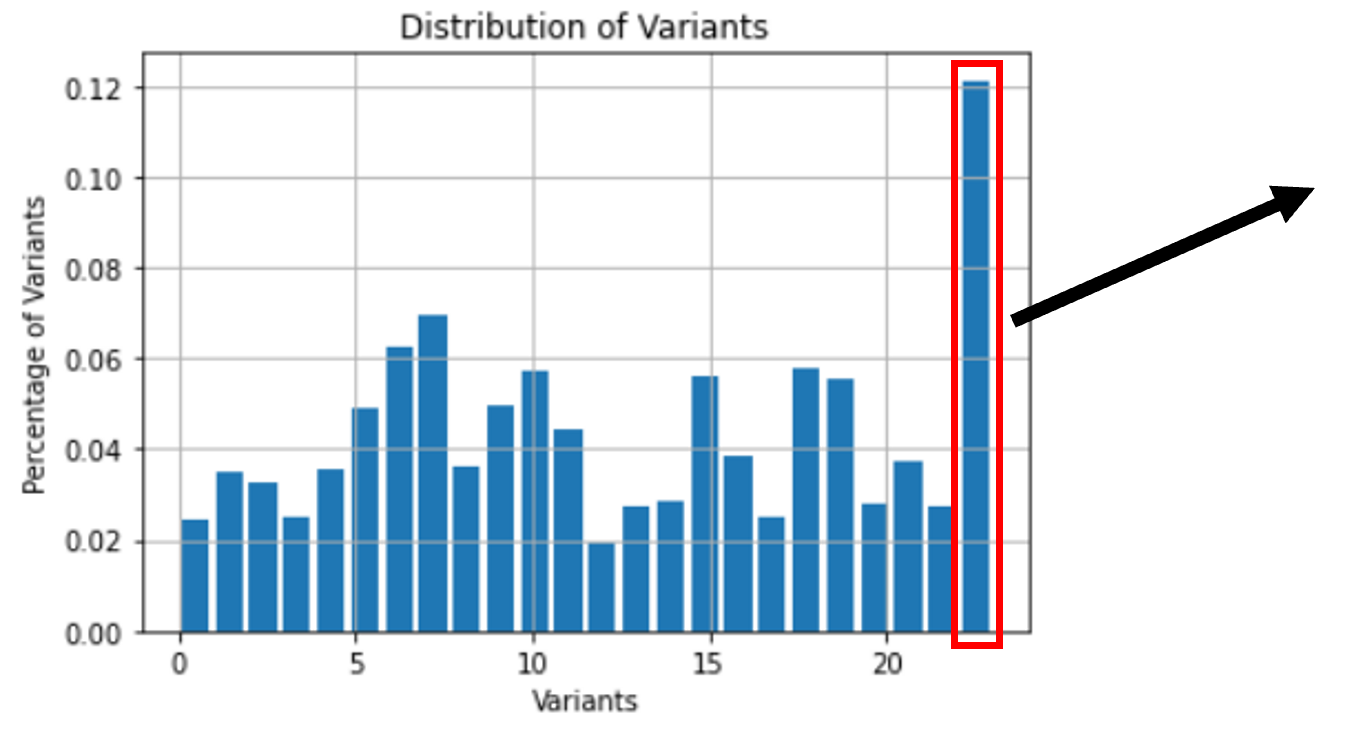

- Automatically monitor size and distribution of all microstructural elements

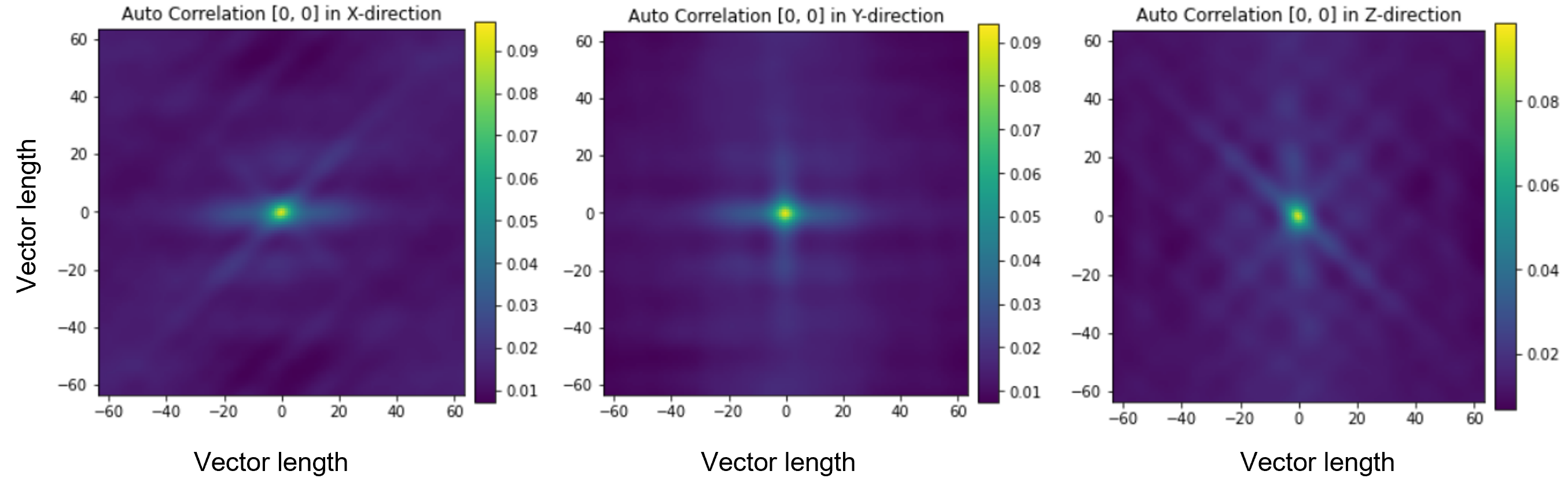

- Apply autocorrelation functions for application-specific materials characteristics

- Provide 3-D information for correlation with 2-D experimental micrographs