High Temperature Superalloys

Key Solutions

- Optimize solutions and prediction of heat treatment.

- Generate artificial microstructures for Finite Element Analysis.

- Analyze microstructure evolution during high-temperature loading.

- Predict creep strain and damage based on thermal and loading history.

Advanced Features

- Coherency loss between γ and γ′ phase.

- Accumulation of dislocations around γ′ phase.

- Diffusion-controlled directional evolution of the microstructure.

- Coalescence of γ′ precipitates.

- Topological inversion of microstructure.

- Local plastic deformation and shear bands creation.

OpenPhase Capabilities

Discover how OpenPhase's advanced phase-field modeling capabilities can revolutionize your high-temperature superalloy development

Advanced Simulation Features

-

Heat Treatment Optimization Different heat treatments to produce varying sizes of γ′ precipitates.

-

Local Stress Analysis Calculation of local stresses based on misfit and external loads.

-

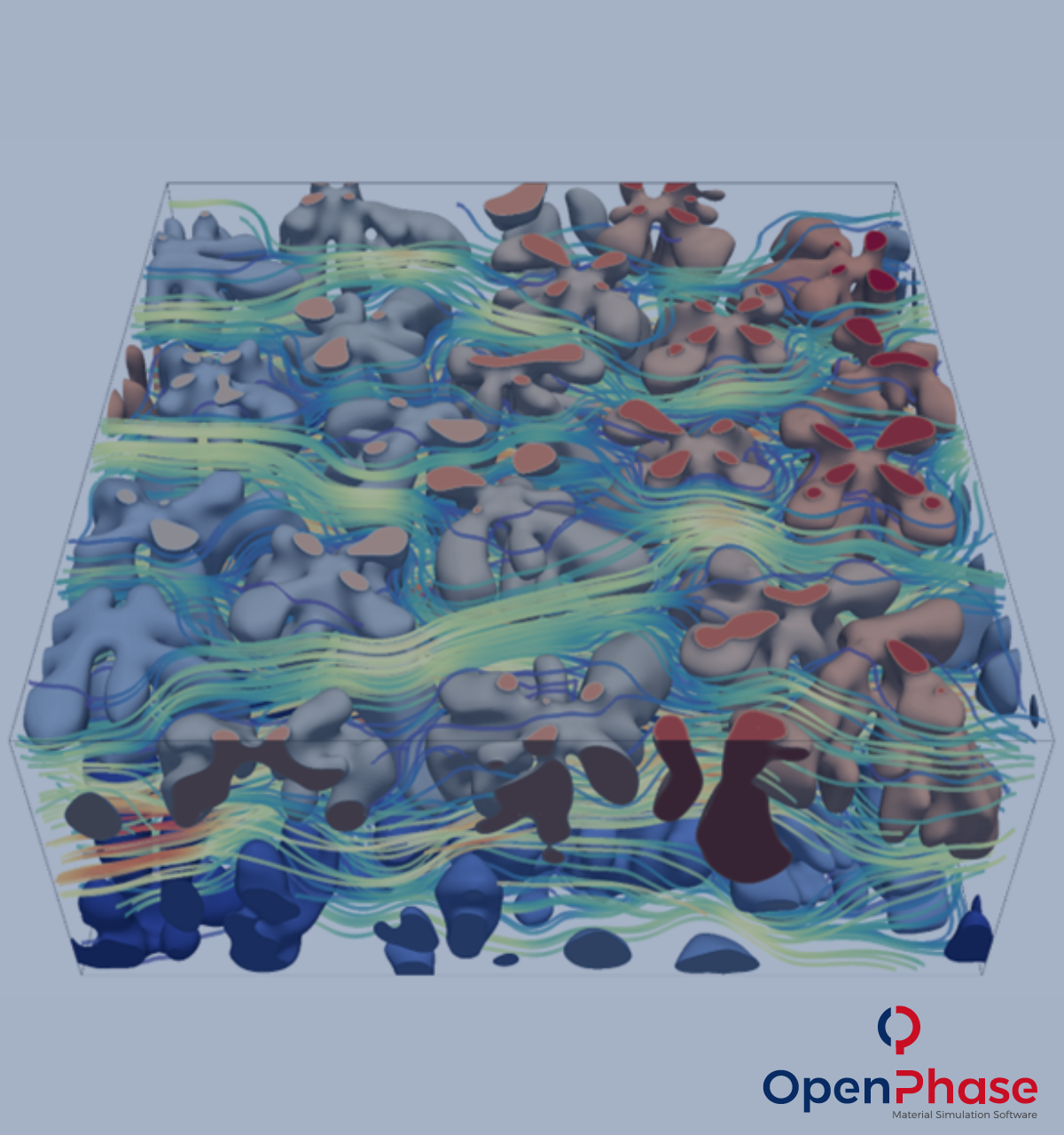

Directional Evolution Directional evolution of microstructure under elastic or elastic-plastic environments.

-

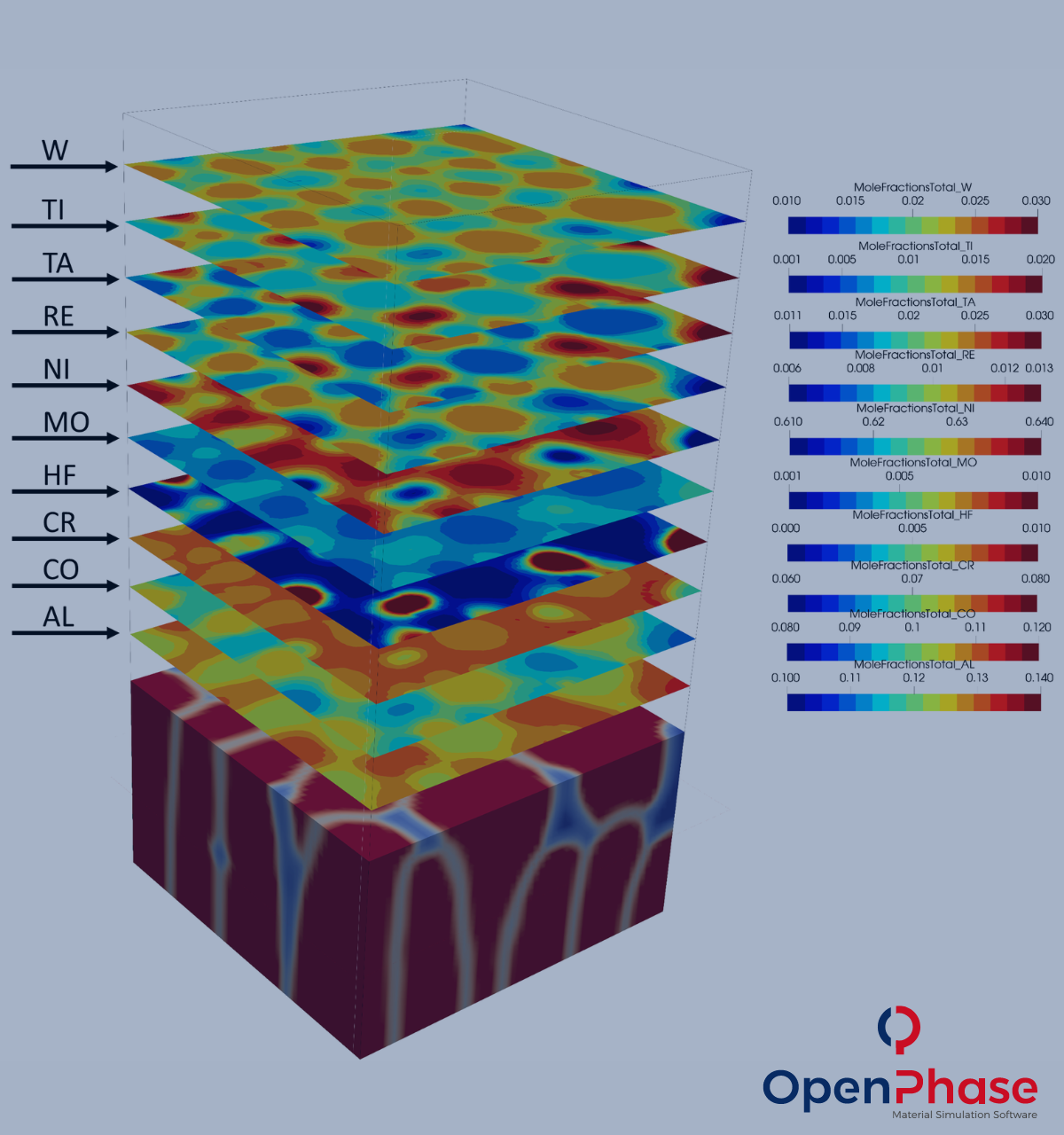

Alloying Effects Impact of alloying elements on microstructure evolution and creep properties.

-

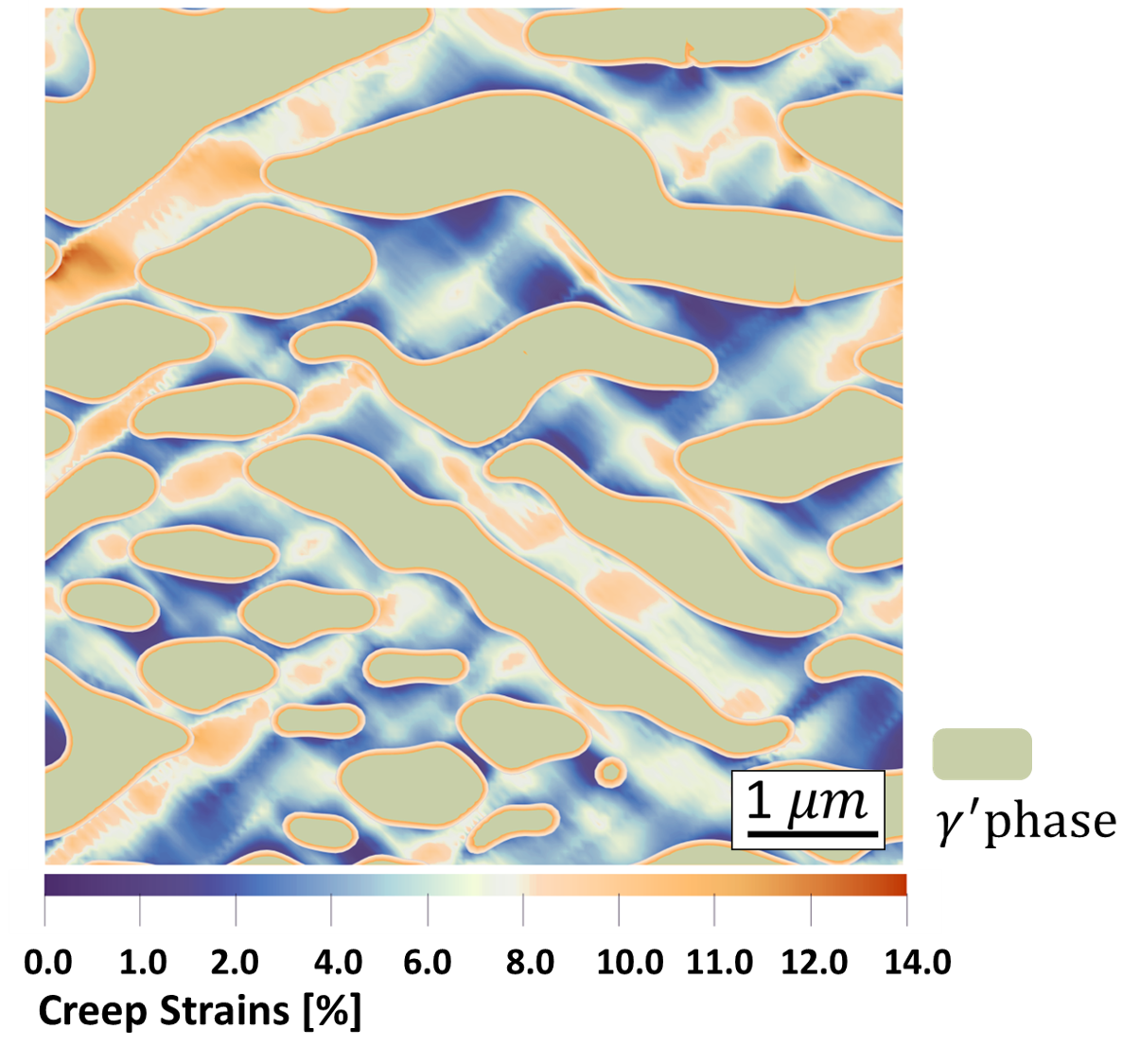

Deformation Analysis Non-homogeneous elastic and plastic deformation of superalloys.

-

Shear Band Impact Effect of shear bands on microstructural evolution.

-

Crystal Rotation Local crystal rotations during creep and plastic deformation.

-

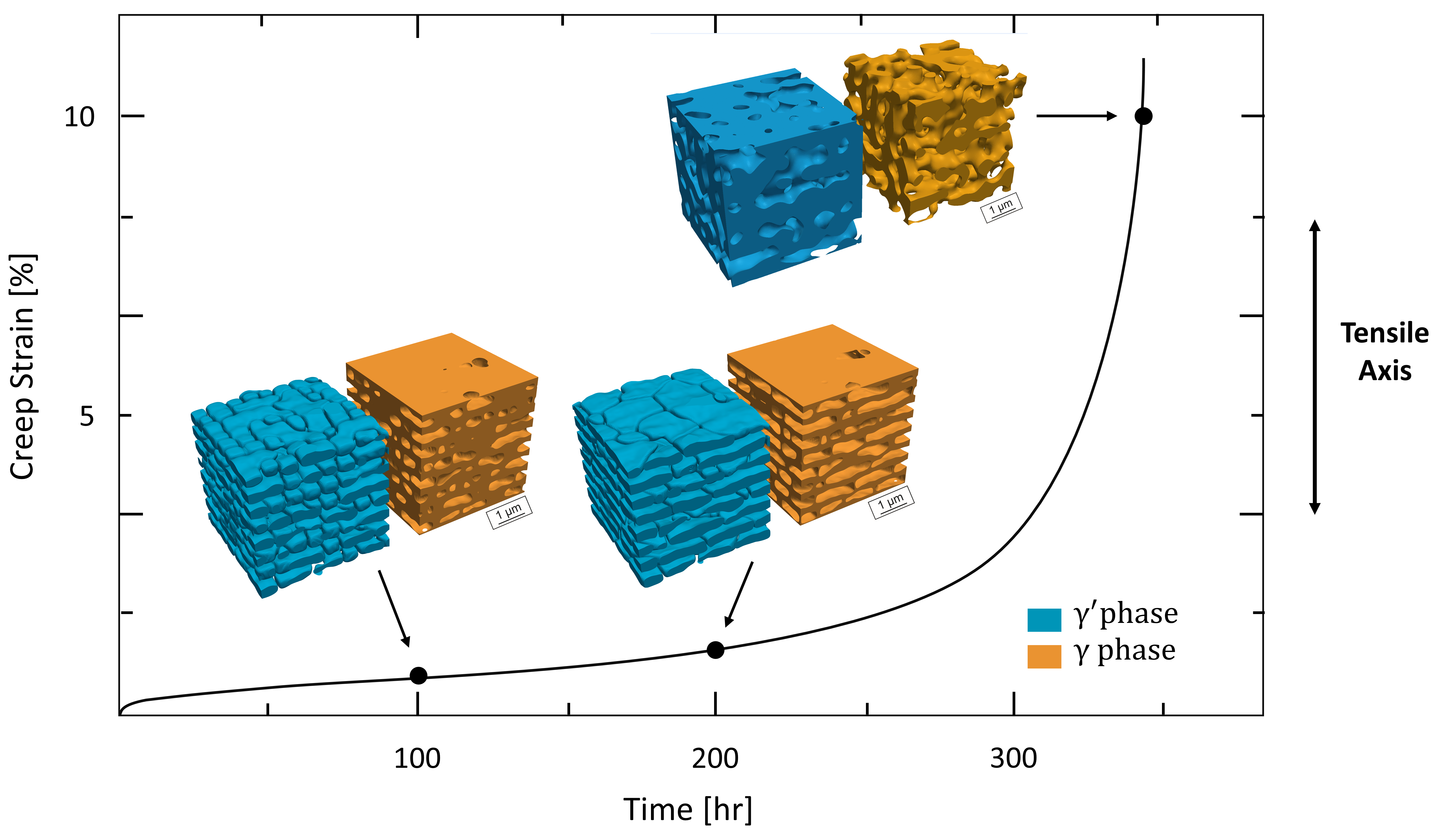

Rafting Analysis Rafting of microstructure leading to topological inversion.

Microstructure Evolution Analysis

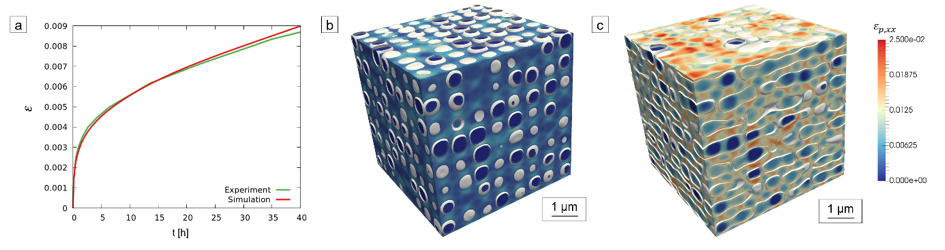

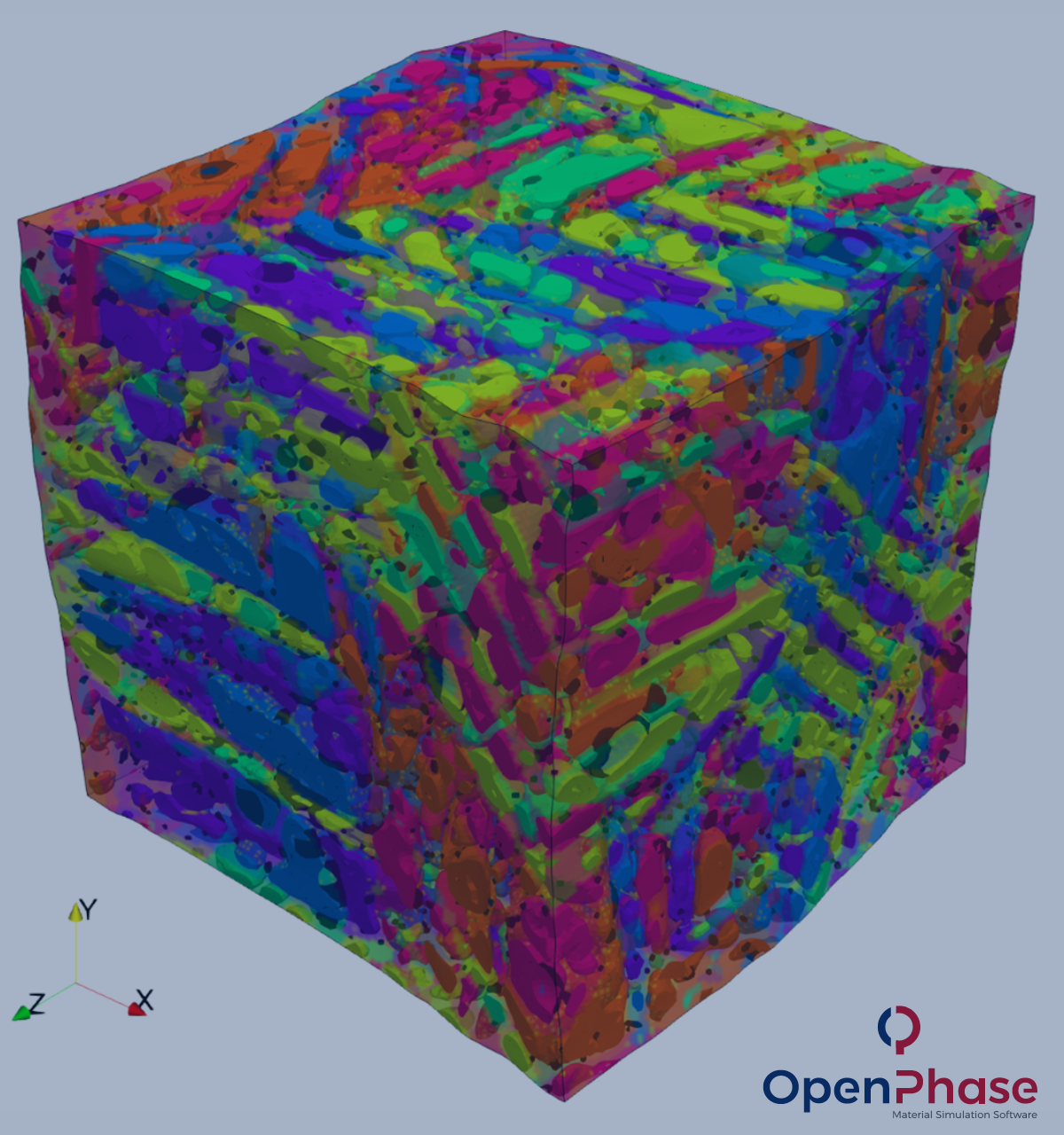

OpenPhase excels at simulating microstructure evolution by considering various physical effects. For example, simulating creep in Ni-base superalloys at 950°C and 350 MPa stress involves the interaction of interface kinetics, diffusion, plasticity, and elasticity.

Our approach is versatile and can be applied to different material systems and processes where phase transformation and/or plasticity are critical, including tensile tests and heat treatments.

Mechanical Properties Simulation

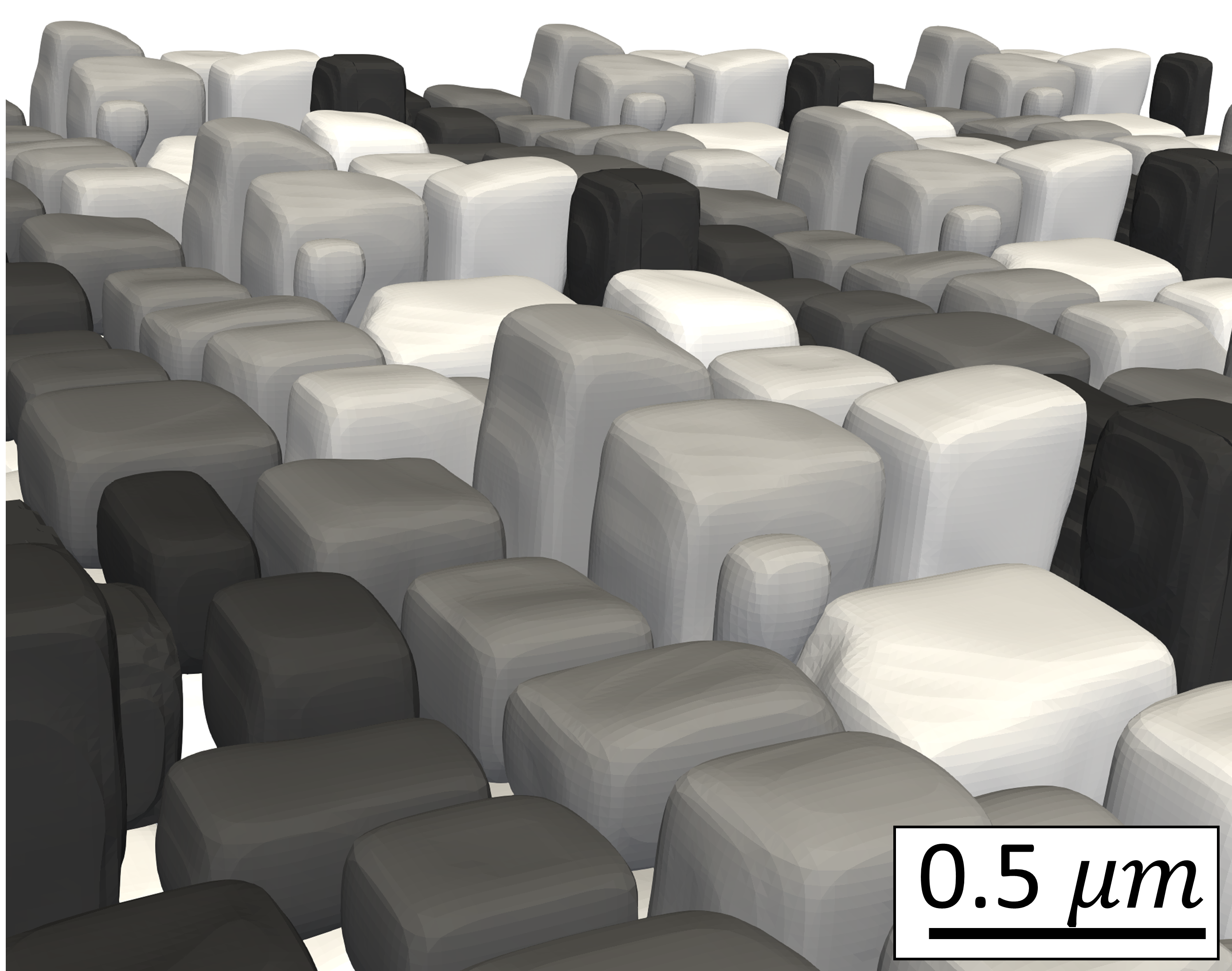

Mechanical properties are crucial for metallic materials, determined by grains, phases, precipitates, and defects within the microstructure. In nickel-base superalloys, the unique microstructure formed by gamma (γ) and gamma-prime (γ′) phases embedded in a gamma matrix evolves during creep deformation, resulting in exceptional creep resistance.

Related Topics

Tempered Martensite

Explore the transformation and properties of tempered martensite in steel materials.

Fluid Dynamics

Discover advanced fluid dynamics simulation capabilities for complex flow scenarios.

Additive Manufacturing

Learn about advanced simulation solutions for additive manufacturing processes.