Additive Manufacturing

About Additive Manufacturing

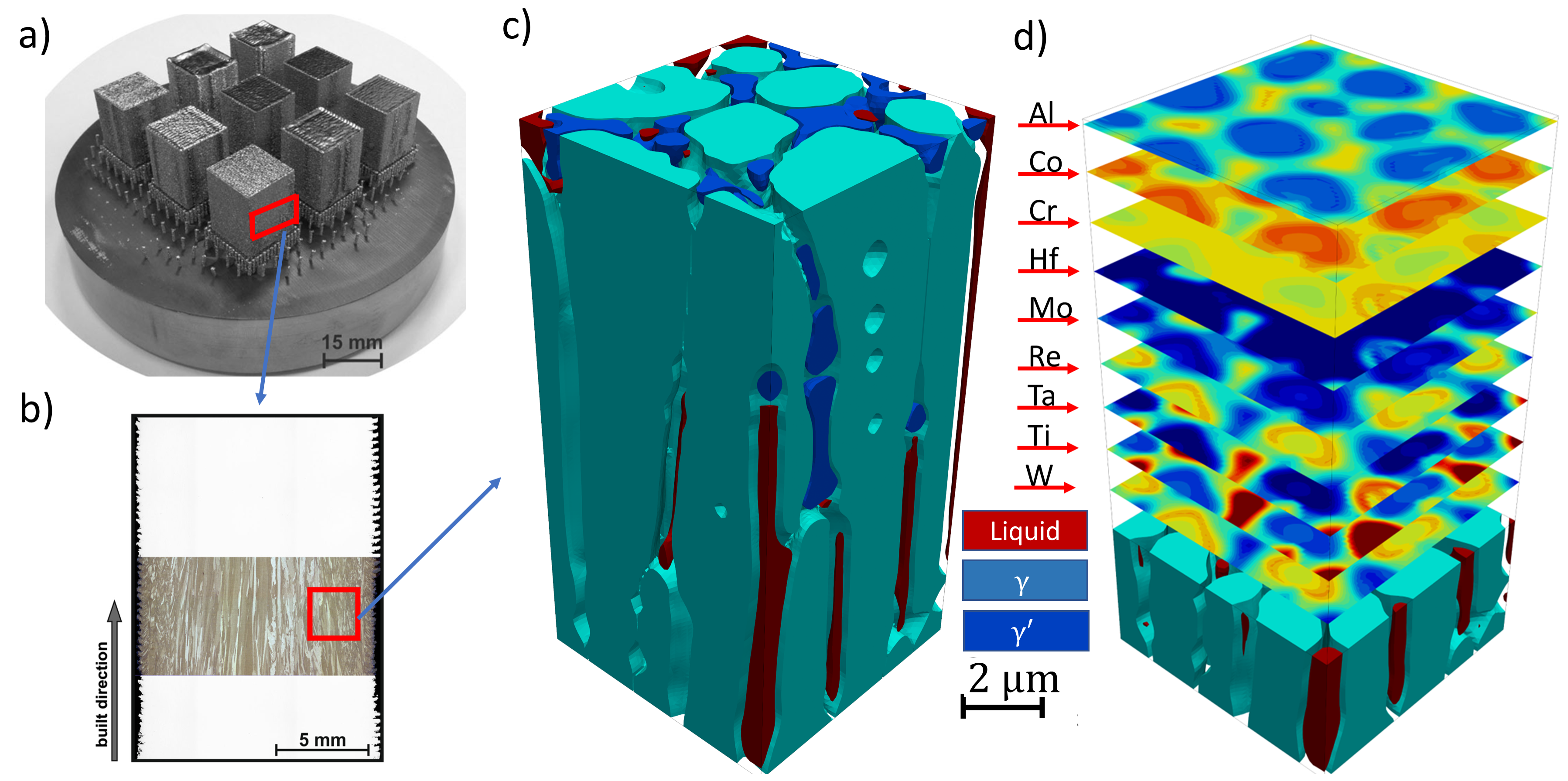

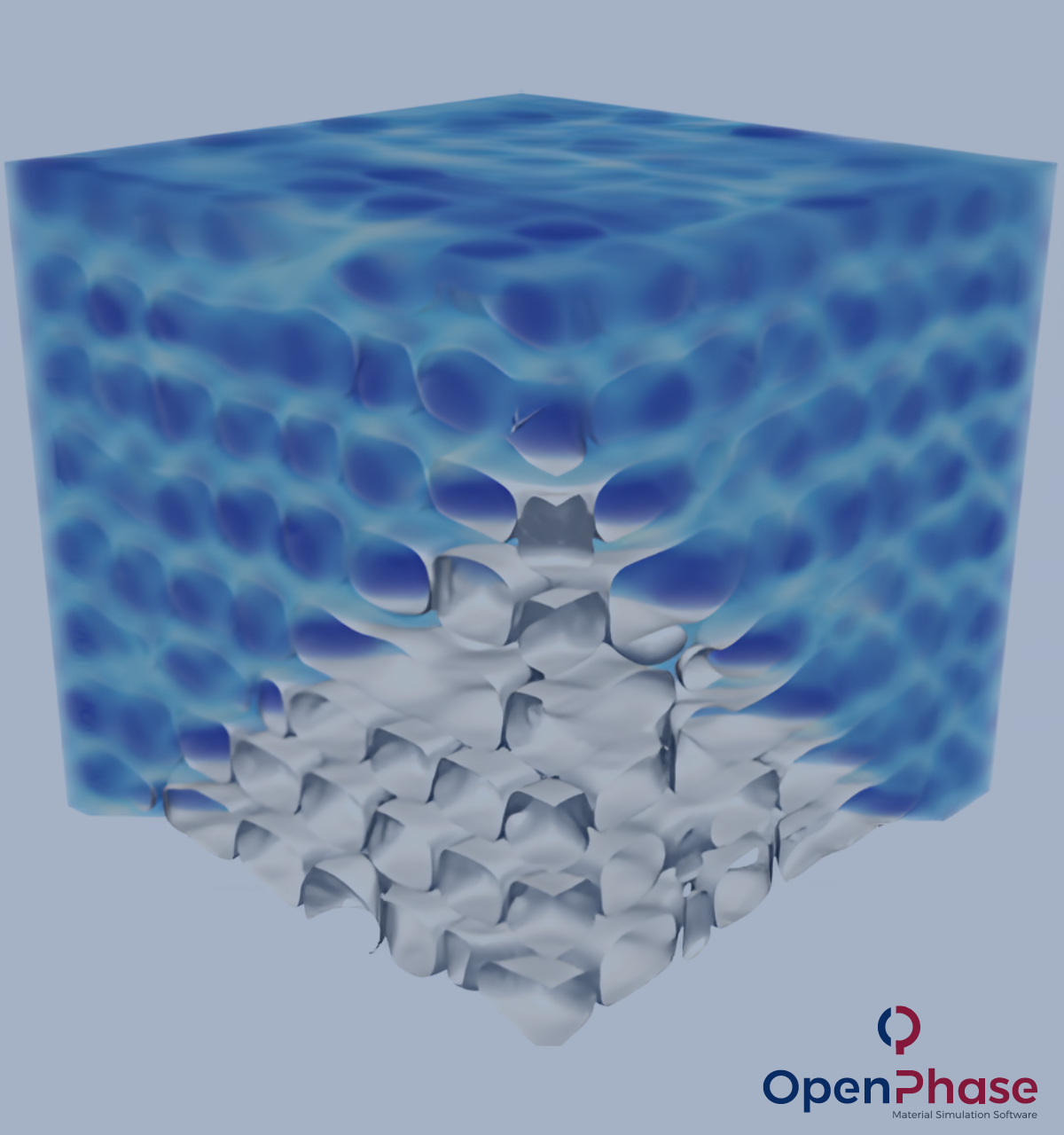

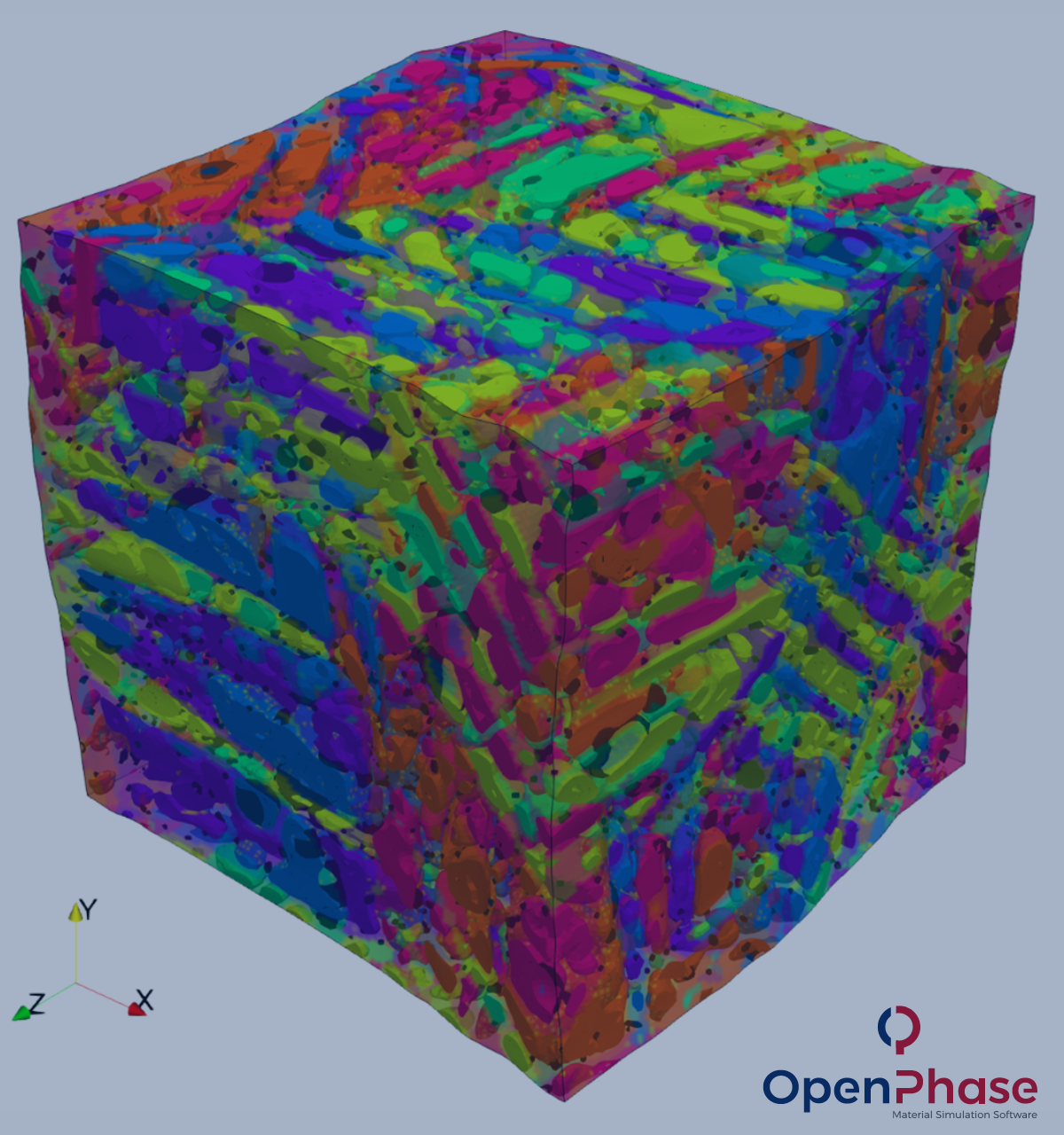

Additive manufacturing (AM) subjects materials to extremely high cooling rates and thermal gradients, resulting in unique microstructures and material properties. OpenPhase provides detailed insights into microstructure evolution in the context of additive manufacturing. Process parameters control dendrite spacing and shape, concentration gradients, nucleation kinetics, and mechanical properties. OpenPhase evaluates these properties through simulation of physics-based models resolved in space and time.

Key Solutions

- Improve the accuracy of macroscopic heat conduction models.

- Microstructure tailoring by understanding the influence of process parameters on nucleation, solidification length scale, and grain morphology.

- Design effective homogenization schemes.

- Expand the selection of materials with the help of multicomponent diffusion.

OpenPhase Capabilities

Discover how OpenPhase's advanced phase-field modeling capabilities can revolutionize your additive manufacturing processes

Improve the Accuracy of Macroscopic Heat Conduction Models

-

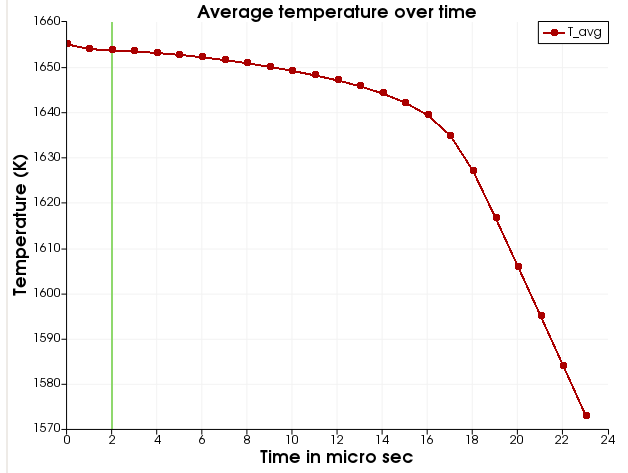

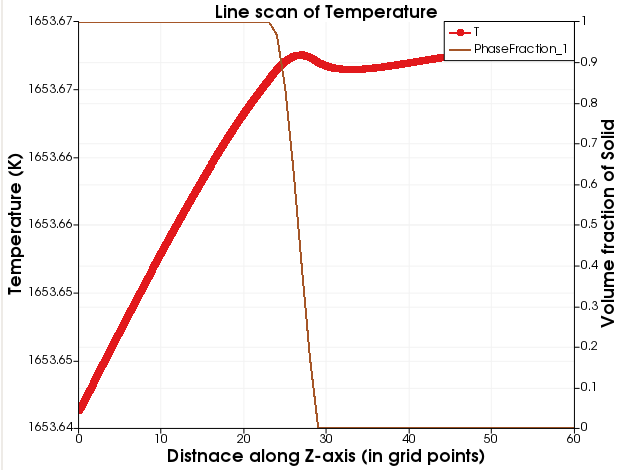

Precise Thermal Control The implicit heat conduction model gives precise control over thermal boundary conditions specific to the additive manufacturing process.

-

Latent Heat Modeling Accurate modeling of latent heat release, thereby affecting the effective cooling rate during solidification.

-

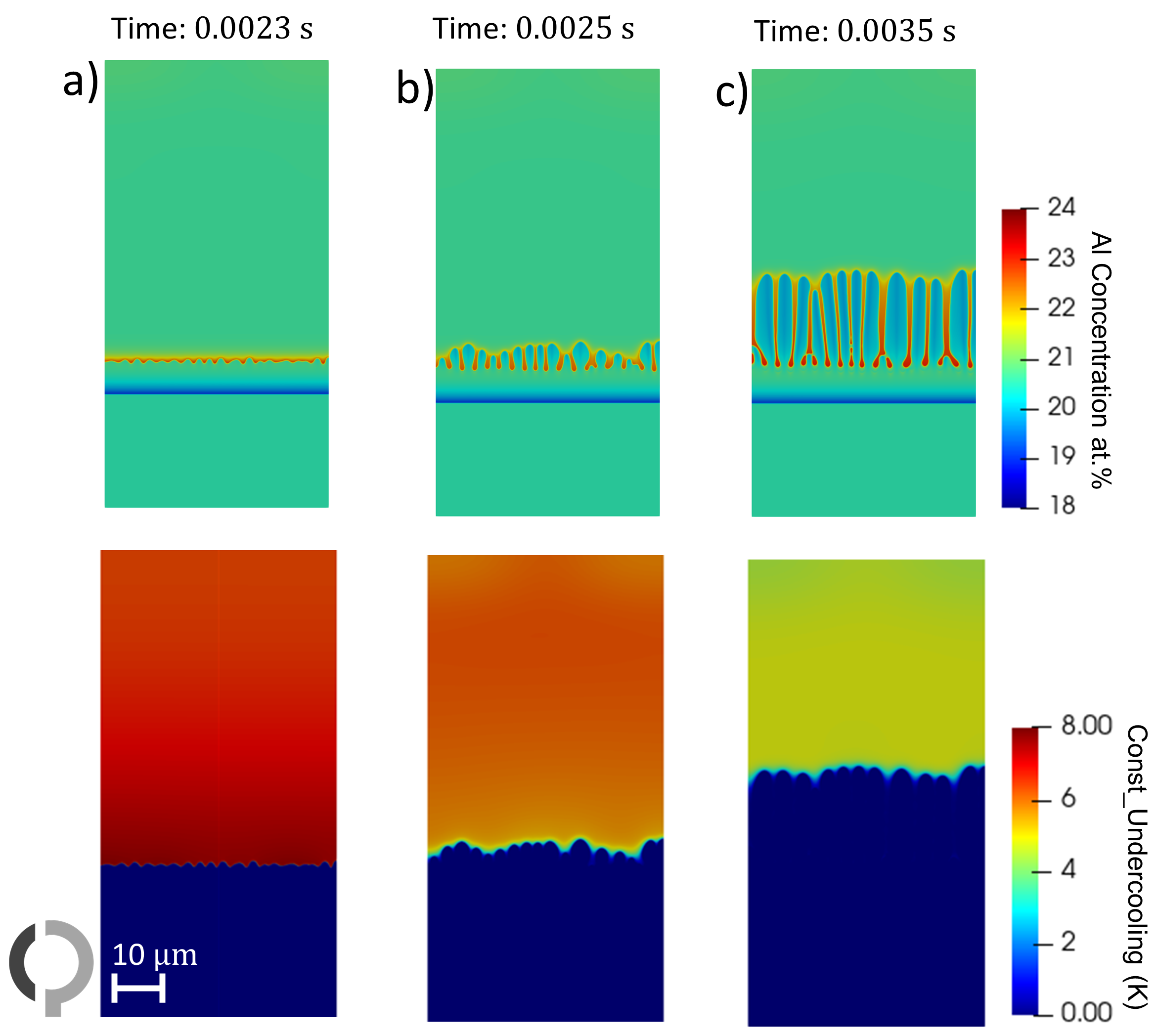

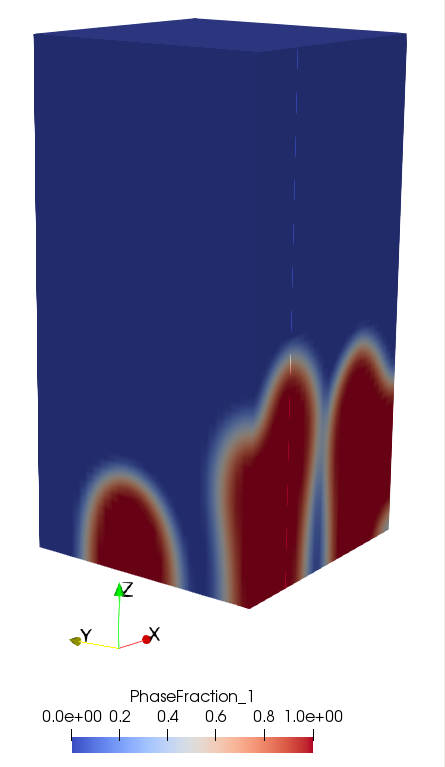

Solidification Analysis Obtain solidification velocity and tip undercooling, which significantly influence grain morphology.

-

Remelting Simulation OpenPhase also enables modeling partial remelting of previously built layers.

Microstructure Tailoring by Understanding the Influence of Process Parameters

-

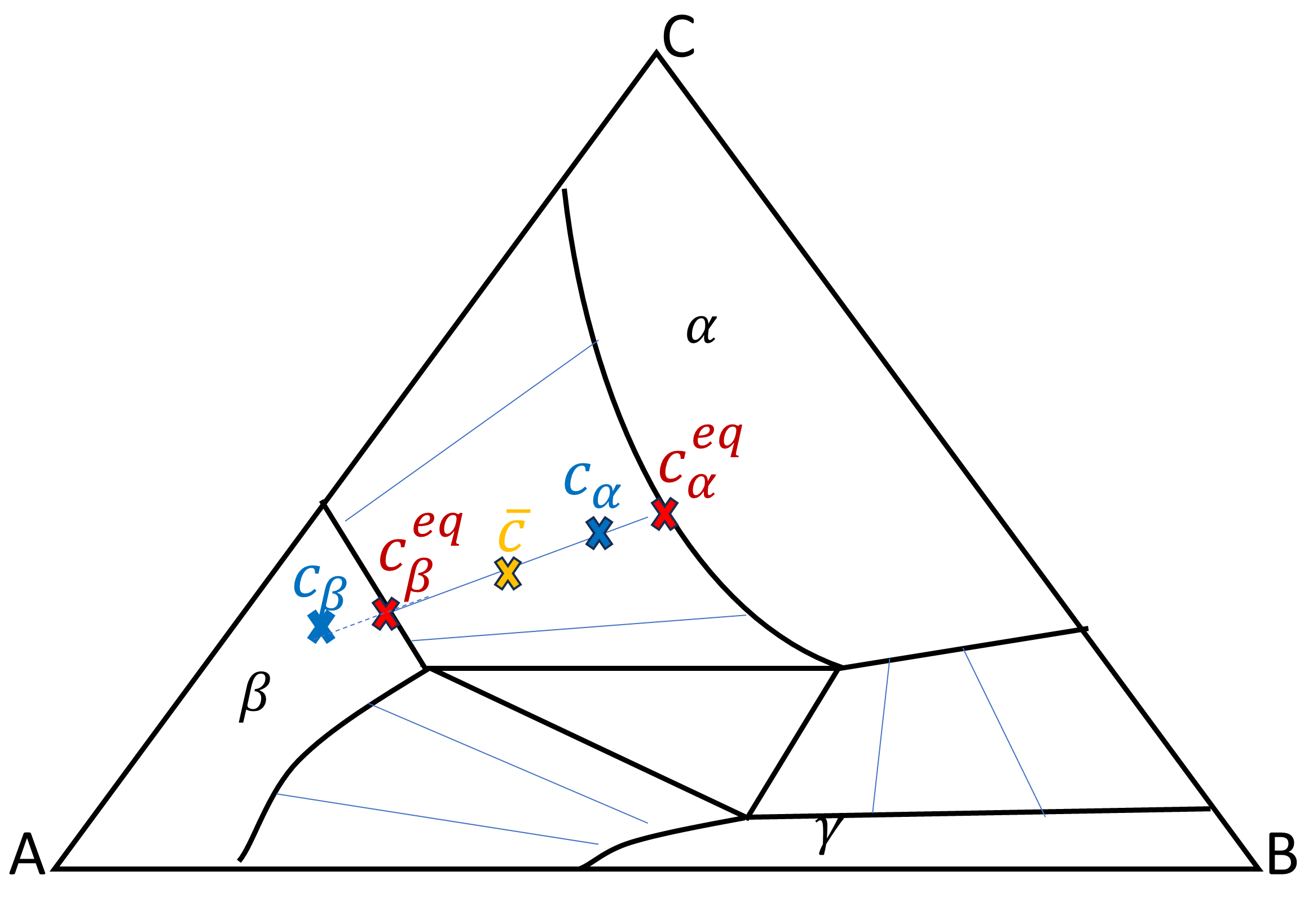

Process Parameter Analysis AM involves several critical process parameters, making it difficult to understand the influence of each on grain morphology. With OpenPhase, it is possible to estimate the dendrite arm spacings and solidification grain morphologies for given process conditions.

-

Grain Structure Control Based on the application, either equiaxed or columnar grain structures are preferred. With OpenPhase, control the grain morphology by modeling the nucleation of primary and secondary phases specific to thermal boundary conditions and chemical compositions.

-

Single-Crystal Optimization For single-crystal microstructures, it's crucial to restrict nucleation resulting from partial remelting of previously built layers. OpenPhase helps estimate solute undercooling from remelting and adjust process parameters accordingly.

-

Segregation Analysis Understand the segregation behavior of alloying elements at interdendritic regions and within primary and secondary phases.

Design Effective Homogenization Schemes

-

Temperature Analysis Estimate the solvus temperatures for the secondary phases.

-

Homogenization Time Estimate the time required for complete homogenization of the system.

-

Melting Prevention Avoid incipient melting by understanding microsegregation after complete solidification.

Expand Material Selection with Multicomponent Diffusion

-

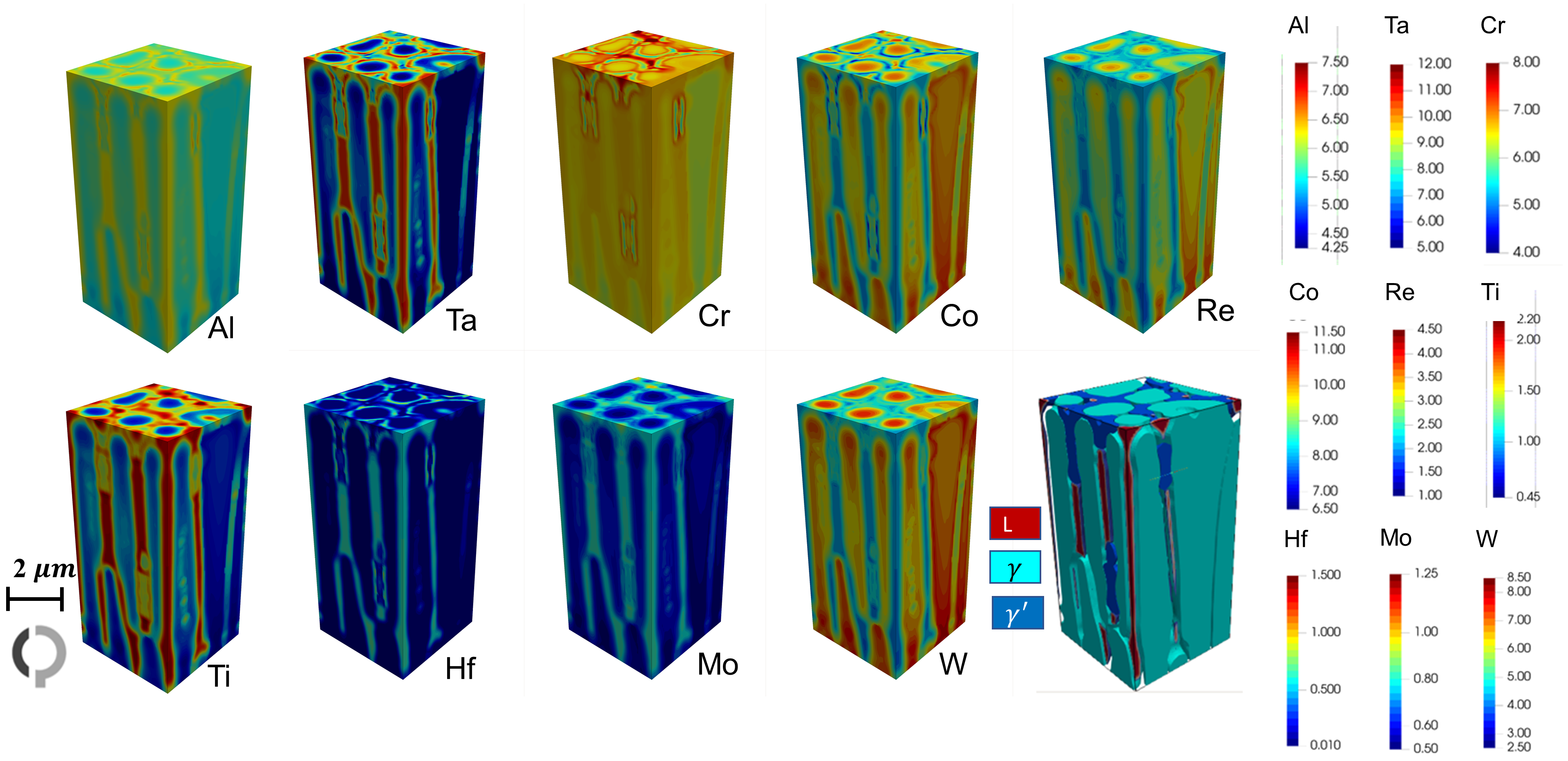

Complete Alloy Modeling With TC-Coupling, OpenPhase enables modeling solidification of the entire alloy composition.

-

Direct Thermodynamic Integration Gibbs energies, chemical diffusivities, and kinetic mobilities are obtained directly from the thermodynamic database.

-

Advanced Microsegregation Analysis Understand microsegregation of different alloying elements in each phase due to varying chemical diffusivities.

Related Topics

High Temperature Superalloys

Discover advanced simulation solutions for high temperature superalloy applications.

Tempered Martensite

Explore the transformation and properties of tempered martensite in steel materials.

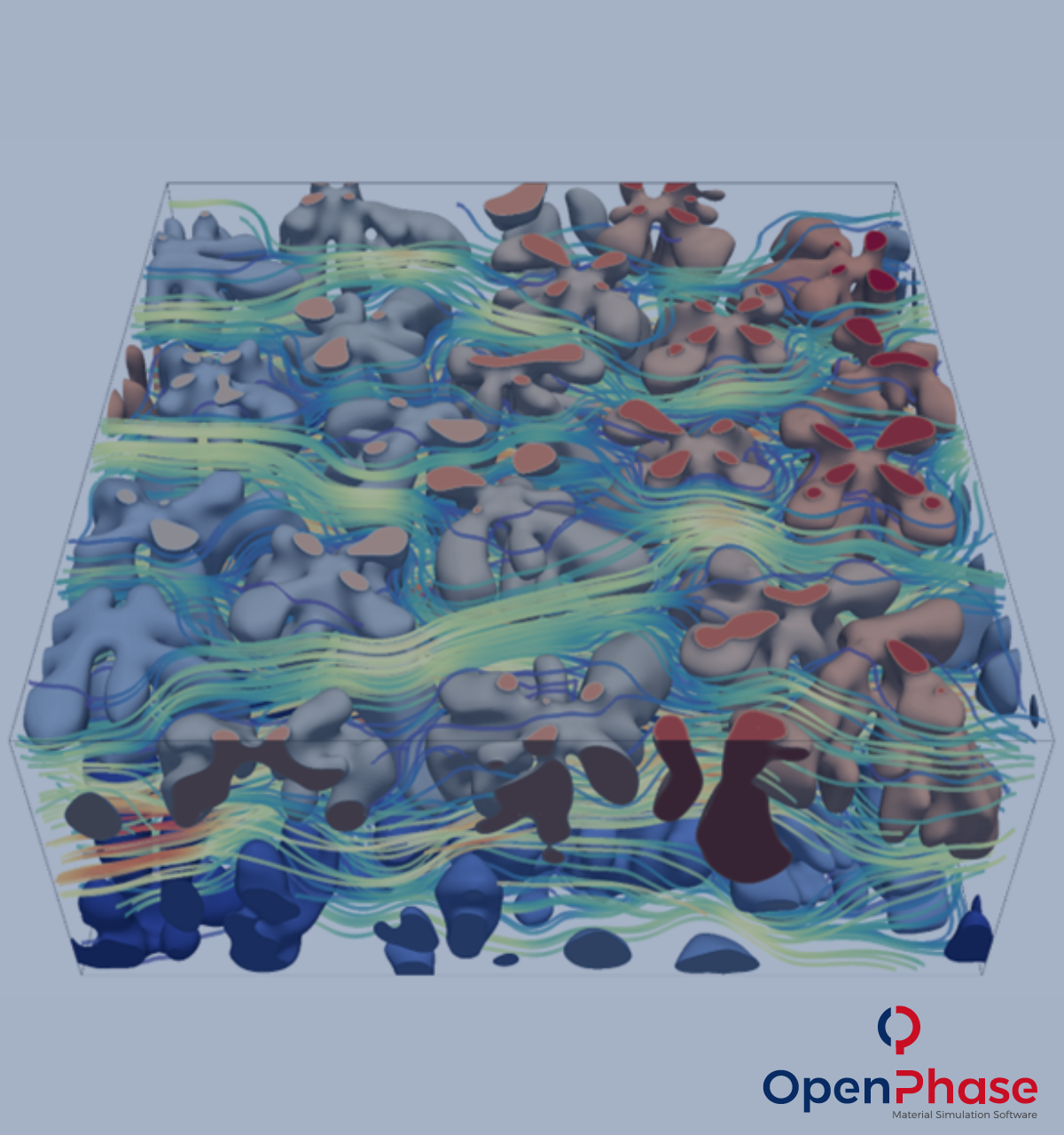

Fluid Dynamics

Discover advanced fluid dynamics simulation capabilities for complex flow scenarios.