Mechanical property prediction

About OpenPhase Application

OpenPhase provides advanced mechanical property prediction capabilities through phase-field modeling. The software enables precise control over phase transformations, heat treatment processes, and mechanical performance optimization. By combining simulation with experimental validation, OpenPhase delivers accurate predictions of material behavior under various conditions.

Key Solutions

- Determine optimal holding temperature and cooling rates

- Refine heat treatment processes for targeted microstructures

- Enhance tensile performance through simulation-experiment comparison

- Predict mechanical properties based on microstructural evolution

OpenPhase Capabilities

Discover how OpenPhase's advanced phase-field modeling capabilities can revolutionize your mechanical property prediction processes

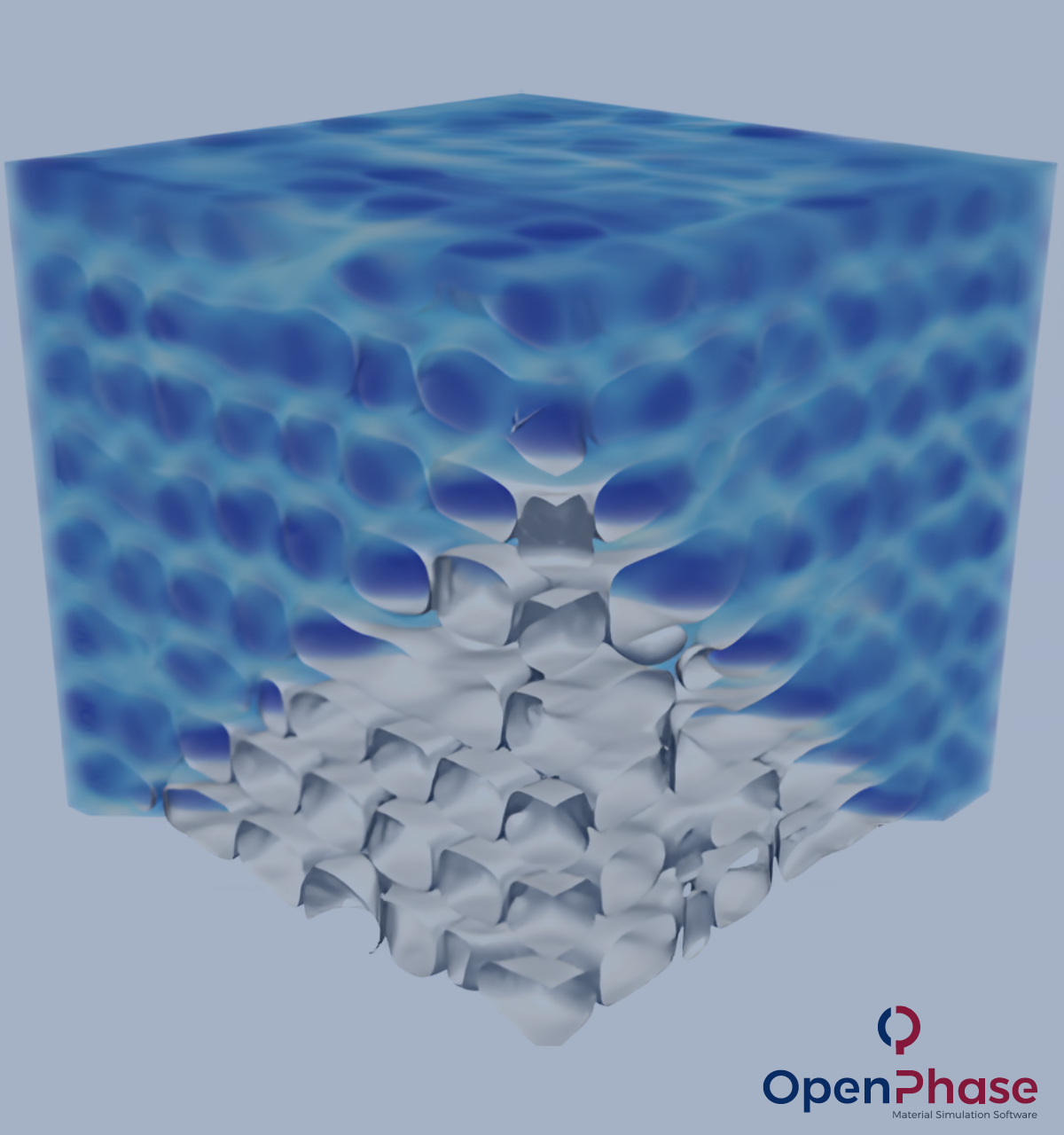

Determine Holding Temperature and Cooling Rate for Controlled Phase Transformation

- Phase-Field Simulation for Thermal Optimization: Model bainitic phase transformation using the phase-field method to determine the optimal holding temperature and cooling rate.

- Grain and Phase Evolution Control: Simulate and analyze grain growth and bainite morphology to refine thermal processing parameters.

- Optimized Cooling Strategies: Adjust cooling rates to control bainite formation, phase fractions, and grain refinement for desired properties.

- Process Optimization for Mechanical Performance: Utilize the simulated microstructure as a foundation for optimizing heat treatment parameters to achieve desired mechanical properties.

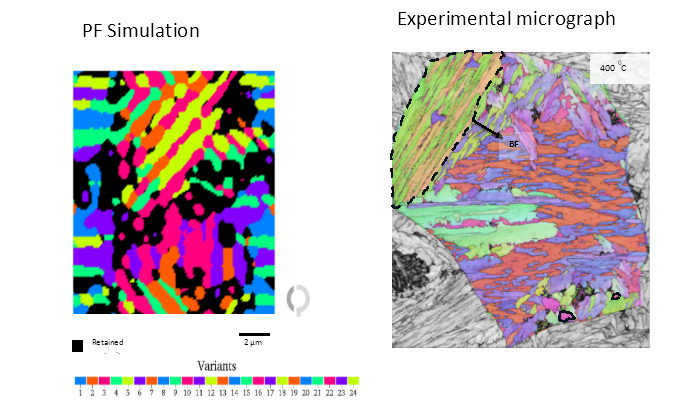

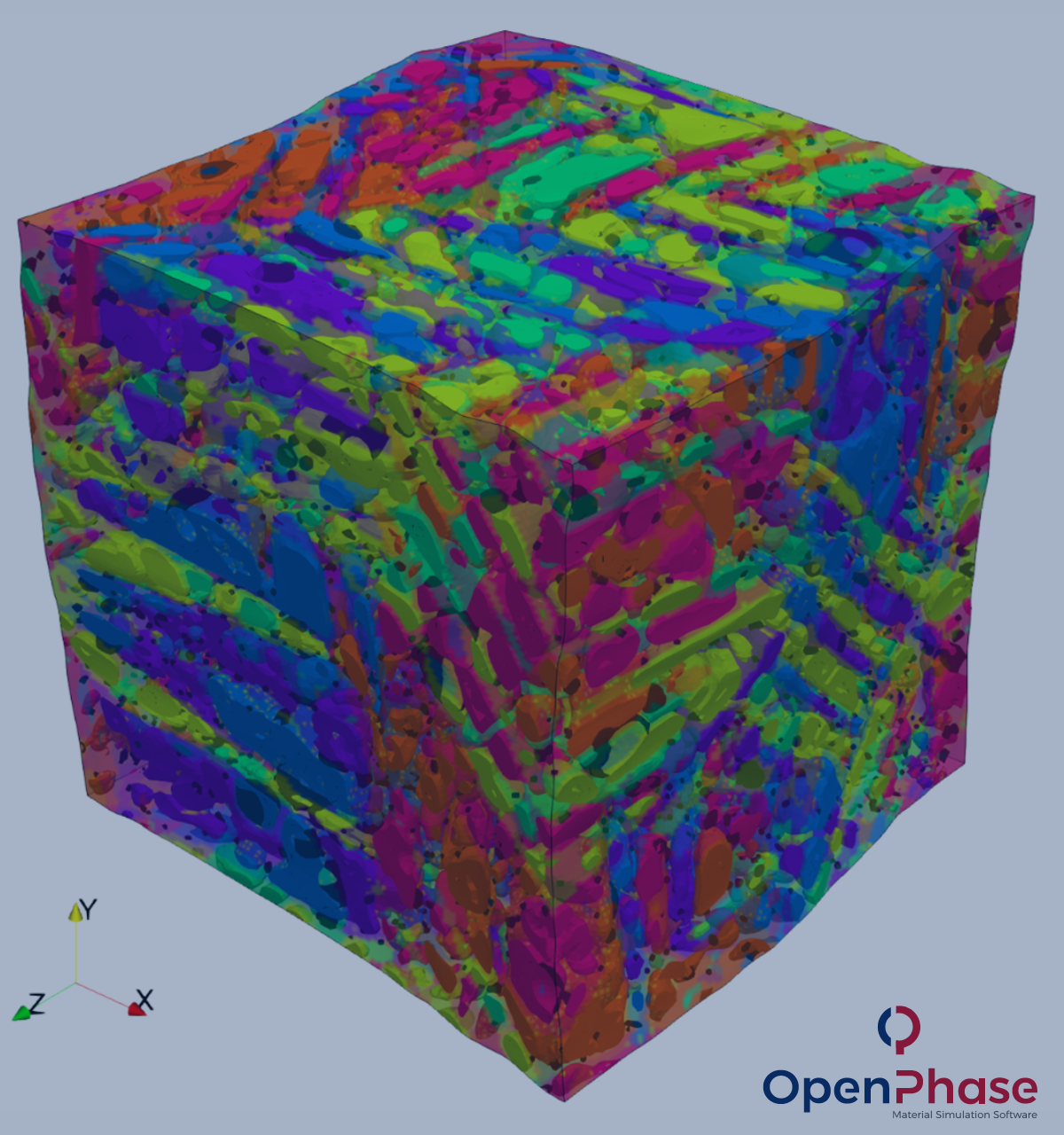

Refine Heat Treatment Processes for Targeted Microstructural Development

- Heat Treatment Simulation: Model phase transformations under different heat treatment conditions to optimize microstructural evolution.

- Microstructure Accuracy and Stability: Ensure the simulated microstructure accurately represents bainite plate size and phase distribution under different thermal conditions.

- Experimental Validation: Compare simulated results with experimental data obtained from techniques like SEM to ensure accuracy.

- Microstructure-Property Correlation: Link heat treatment parameters to final mechanical properties, ensuring tailored performance for specific applications.

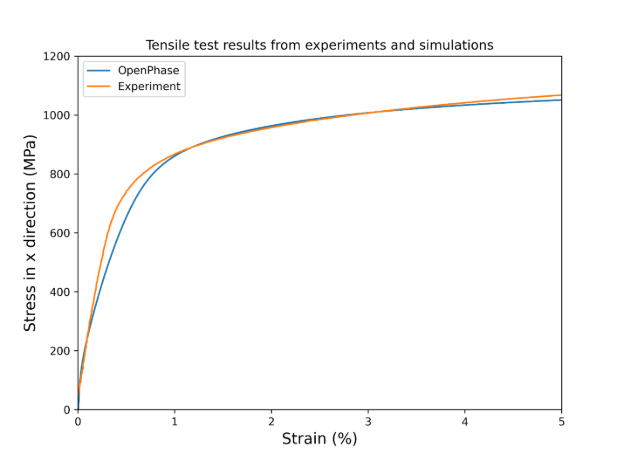

Enhance Tensile Performance Through Simulation-Experiment Comparison

- Simulated Tensile Test Analysis: Extract stress-strain curves, yield strength, and ultimate tensile strength from the simulated microstructure.

- Experimental Data Comparison: Compare simulation results with physical tensile test data to evaluate alignment and accuracy.

- Deformation Behavior Assessment: Analyze the material's response under tensile loading to understand its mechanical performance.

- Model Optimization: Identify and address discrepancies between simulated and experimental results.

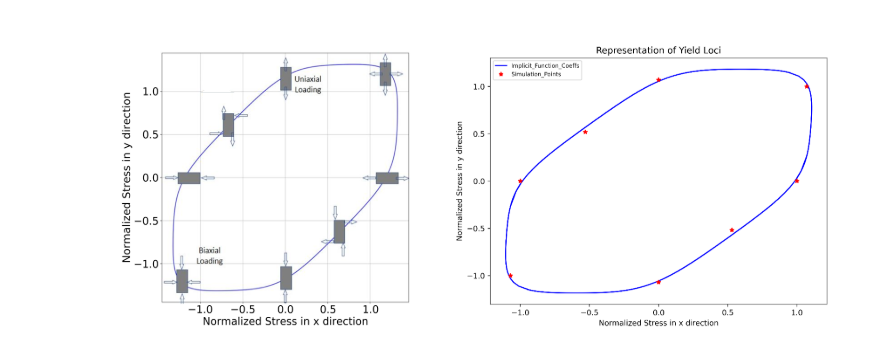

Predict Mechanical Properties Based on Microstructural Evolution

- Barlat91 Yield Criterion Application: Implement the Barlat91 model to predict anisotropic plastic behavior under multiaxial stress conditions.

- Experimental Calibration: Calibrate the model parameters using experimental data to enhance the accuracy of yield surface predictions.

- Yield Surface Visualization: Generate yield surfaces to visualize and analyze the material's deformation response under various loading scenarios.

- Material Performance Insights: Use the predicted yield surfaces to assess and optimize the material's performance in forming and structural applications.

Related Topics

High Temperature Superalloys

Discover advanced simulation solutions for high temperature superalloy applications.

Tempered Martensite

Explore the transformation and properties of tempered martensite in steel materials.

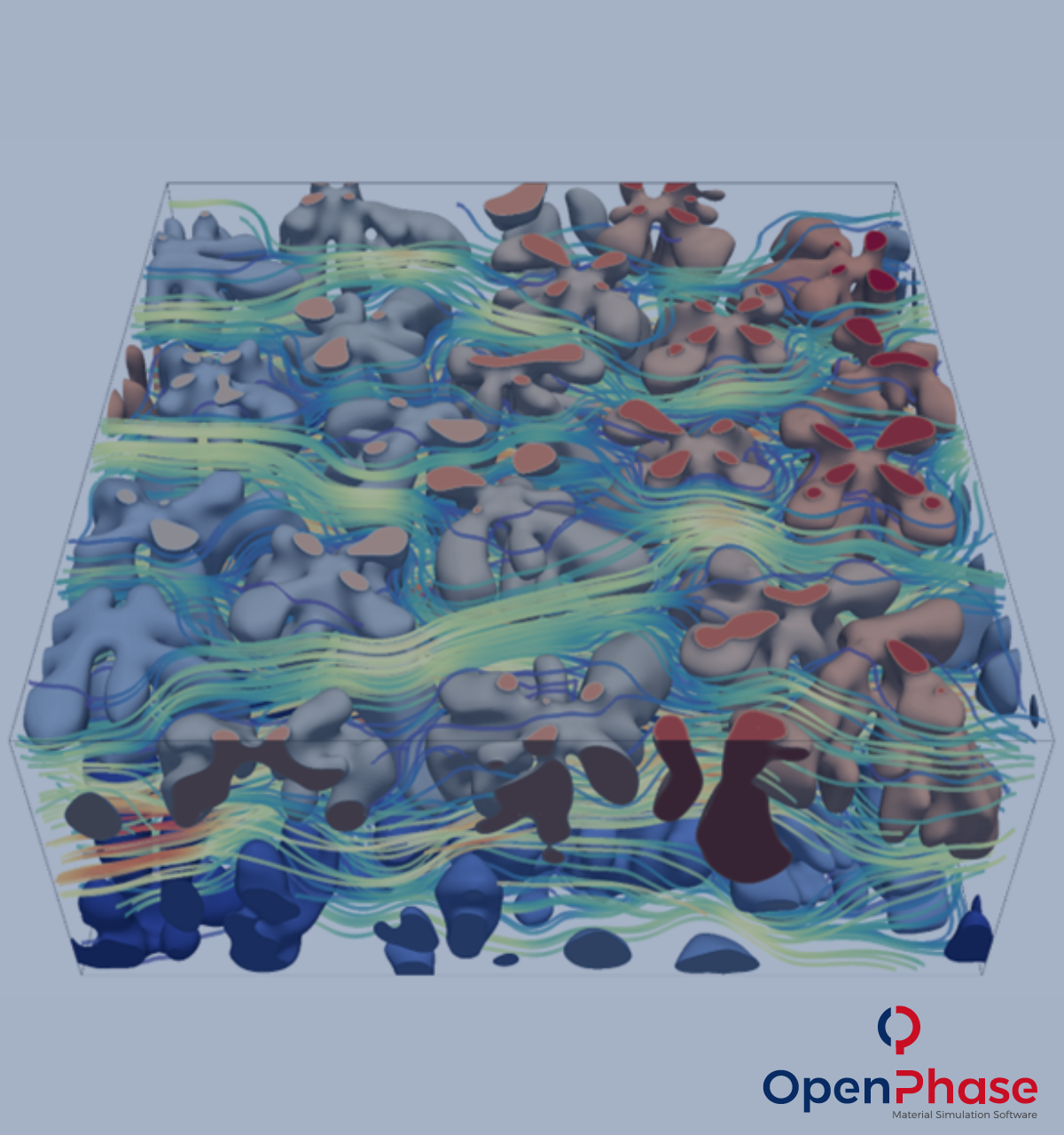

Fluid Dynamics

Discover advanced fluid dynamics simulation capabilities for complex flow scenarios.